WSS Blog

Follow our latest updates and thoughts on our industryTop Types of Warehouse Storage Racks for Efficient Inventory Management?

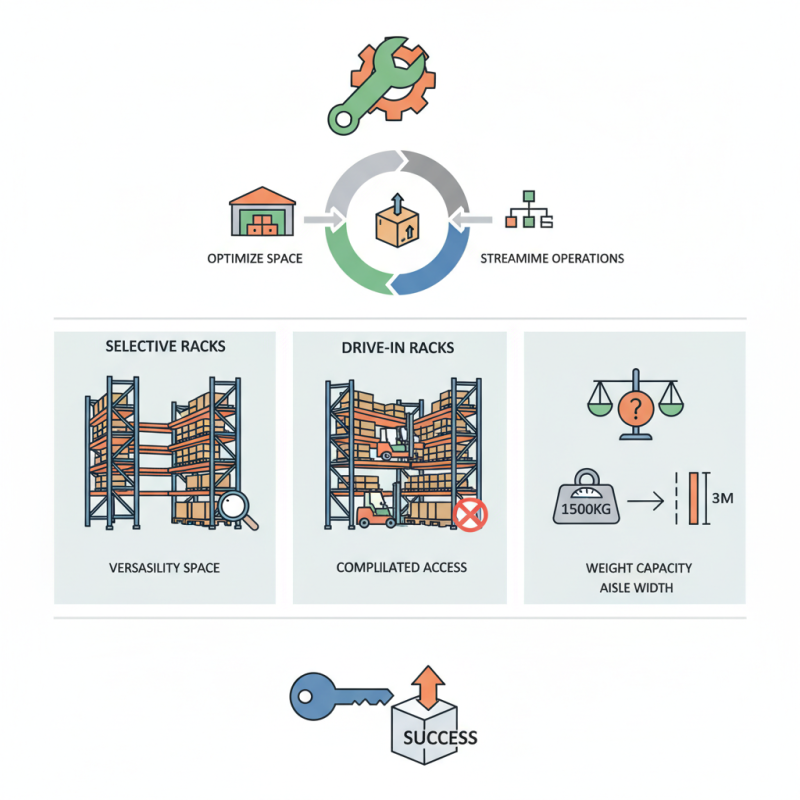

In the realm of inventory management, choosing the right warehouse storage racks is crucial. John Smith, an industry expert with over 15 years of experience, emphasizes, "The right racks can optimize space and streamline operations." Selecting suitable warehouse storage racks can significantly enhance efficiency.

Different types of storage racks cater to various needs. For example, selective racks are common due to their versatility. However, they may not maximize space fully. This highlights the importance of evaluating your specific storage requirements. On the other hand, drive-in racks save space but complicate access to products.

Understanding these nuances is essential for effective inventory management. A mismatch between available racks and inventory type can lead to chaos. Considerations like weight capacity and aisle width should not be overlooked. Finding the balance between function and space can be challenging but rewarding. Proper warehouse storage racks are a key to success in the industry.

Types of Warehouse Storage Racks Overview

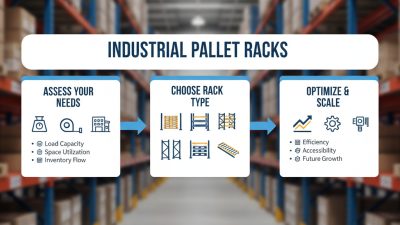

When it comes to warehouse storage racks, there are various types to consider. Each type serves a unique purpose. Pallet racking is one of the most common. It allows for easy access to products. This system is ideal for businesses with high inventory turnover. You can store large quantities on pallets. However, it requires careful organization.

Another option is cantilever racks. These are perfect for long or bulky items. They help maximize vertical space. With cantilever racks, items are easily visible. It’s simple to retrieve stock. Yet, they may not be suitable for smaller items. Proper planning is vital for using this type efficiently.

Drive-in racks provide high-density storage solutions. They are beneficial for storing similar products. But, accessing items can be a challenge. It requires a specific method, known as Last In, First Out (LIFO). This approach may lead to products being forgotten at the back. Thoughtful inventory management is crucial here. Selecting the right storage rack is not always straightforward. The decision must align with specific needs and workflows.

Static vs. Dynamic Storage Rack Systems

In the world of warehouse management, choosing the right rack system can significantly impact efficiency. Static and dynamic storage rack systems each have unique benefits.

Static racks are simple and provide dedicated space for each item. They are cost-effective and easy to install. However, they can lead to space inefficiencies, especially in larger warehouses.

Dynamic storage racks, on the other hand, maximize space by allowing for more fluid movement of products. They use gravity or automated systems to enhance the picking process. Although more complex, these systems can adapt to varying inventory levels. Still, their installation and maintenance can be challenging, which requires careful consideration.

When deciding between static and dynamic racks, think about your inventory flow. Static systems work well for low-rotation items. But larger operations may need the adaptability of dynamic racks. It's essential to weigh these factors carefully. Consider your layout, the frequency of product movement, and even future needs. Each warehouse is unique, and the right choice is not always clear.

Vertical Storage Solutions for Maximizing Space

Vertical storage solutions are crucial for optimizing warehouse space. According to the 2023 Warehouse Efficiency Report, vertical storage can enhance space usage by up to 50%. Utilizing vertical racks allows businesses to make the most of their height rather than just floor space. This shift can lead to reduced costs per square foot, which is essential for many organizations.

One effective solution is to implement pallet- and cantilever-racking systems. These systems support heavier items efficiently. However, they also require careful planning. Overloading the racks can lead to safety hazards and inventory issues. A study shows that 20% of warehouse accidents are due to improper storage. It's vital to train staff on correct load placement and regular maintenance checks.

As vertical storage becomes more popular, businesses must evaluate their logistics strategies continually. Space optimization should not just focus on immediate needs. Consider future growth and flexibility. A well-thought-out storage plan can adapt to changing inventory levels. By analyzing past inventory data and trend reports, warehouses can better prepare for fluctuations, enhancing long-term efficiency.

Top Types of Warehouse Storage Racks for Efficient Inventory Management

Specialty Racking for Unique Inventory Types

When it comes to managing unique inventory types, specialty racking is essential. Different items require different storage solutions. For example, food items often need specific temperature controls. Some chemicals require separation for safety. Therefore, you'll need customized racks to meet these requirements.

Consider pallet flow racks. Items can move easily through them. This type saves time during picking. It also maximizes space. These racks are not just for regular pallets. They can handle diverse products. Ensure proper installation. Poorly installed racks can lead to accidents.

Another tip: think about cantilever racks. These are great for long items like pipes or lumber. They allow for easy access and organization. However, it's vital to monitor the weight limits. Overloading can cause issues.

Reflect on your inventory's specific needs. Assess what racks will best suit your products. Space efficiency is crucial. Regularly review your setup. Are the racks serving their purpose? If not, adjustments may be necessary.

Best Practices for Warehouse Rack Maintenance and Safety

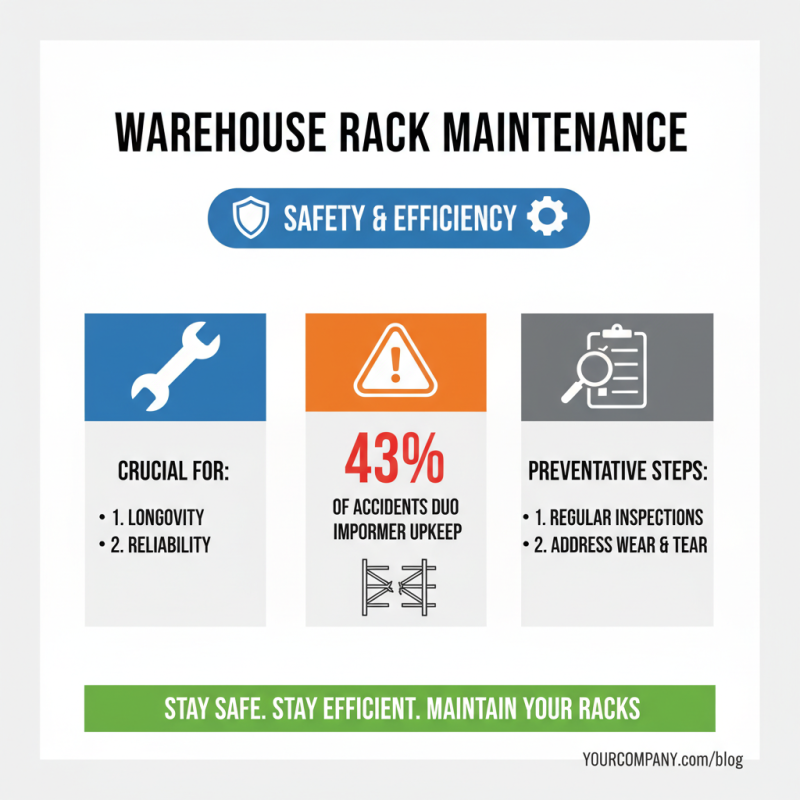

Maintaining warehouse racks is crucial for safety and efficiency. Proper upkeep ensures the longevity of your storage solutions. Industry reports suggest that 43% of warehouse accidents are due to improper rack maintenance. Regular inspections can help identify wear and tear before they become major issues.

Tip: Regularly check for signs of damage. Look for bent beams, loose bolts, or rust. These can compromise the entire structure.

Safety training for employees is essential. A well-trained team reduces risks significantly. Studies show that companies with ongoing safety training experience 30% fewer accidents. Create a culture of safety that encourages reporting hazards.

Tip: Implement a simple checklist for daily inspections. This encourages accountability among staff and promotes proactive maintenance. While it may seem tedious, addressing minor issues quickly can save you from bigger headaches later.

Related Posts

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

2026 How to Choose the Right Uline Pallet Racks for Your Warehouse?

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More