WSS Blog

Follow our latest updates and thoughts on our industryTop 10 Racking and Shelving Systems for Efficient Storage Solutions?

Efficient storage is crucial in today's fast-paced environment. Racking and shelving systems play a significant role in optimizing space and enhancing productivity. According to a report by Warehousing and Logistics International, effective storage solutions can improve warehouse efficiency by up to 30%. This is a considerable boost for many businesses.

Experts emphasize the importance of selecting the right racking and shelving systems. "Choosing the appropriate storage solution can transform your entire operational workflow," states John Smith, a recognized expert in warehouse management. His insights underline the necessity of understanding specific storage needs.

However, many companies still overlook essential factors. Lighting, accessibility, and load capacities often get compromised. Inadequate planning may lead to ineffective space utilization. It’s crucial to reflect on these elements when designing storage systems. Racking and shelving systems should not just be about filling space; they should be strategically enhancing operational effectiveness.

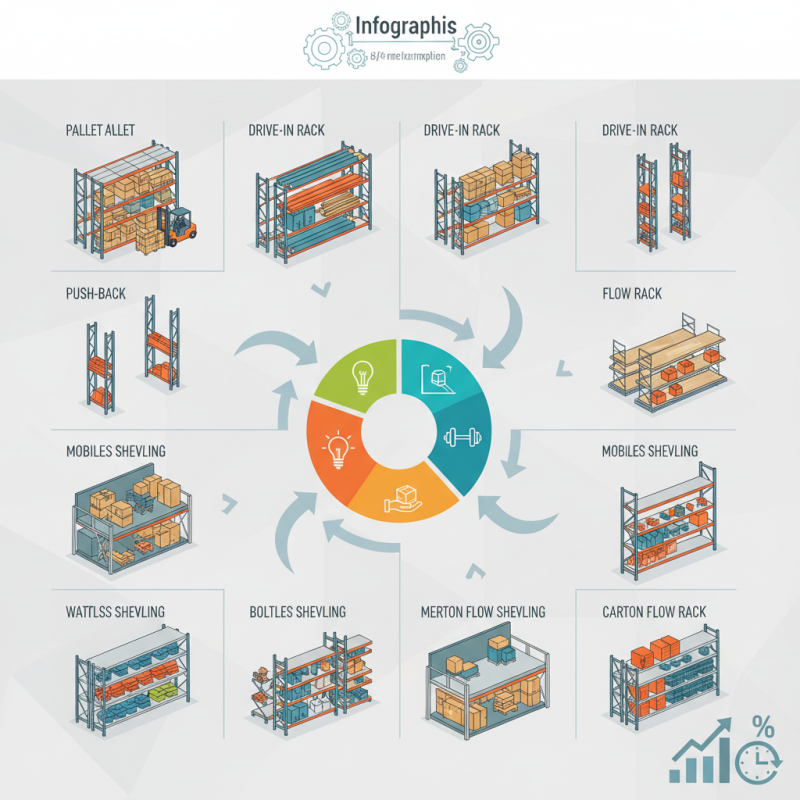

Types of Racking Systems: Understanding Their Unique Benefits

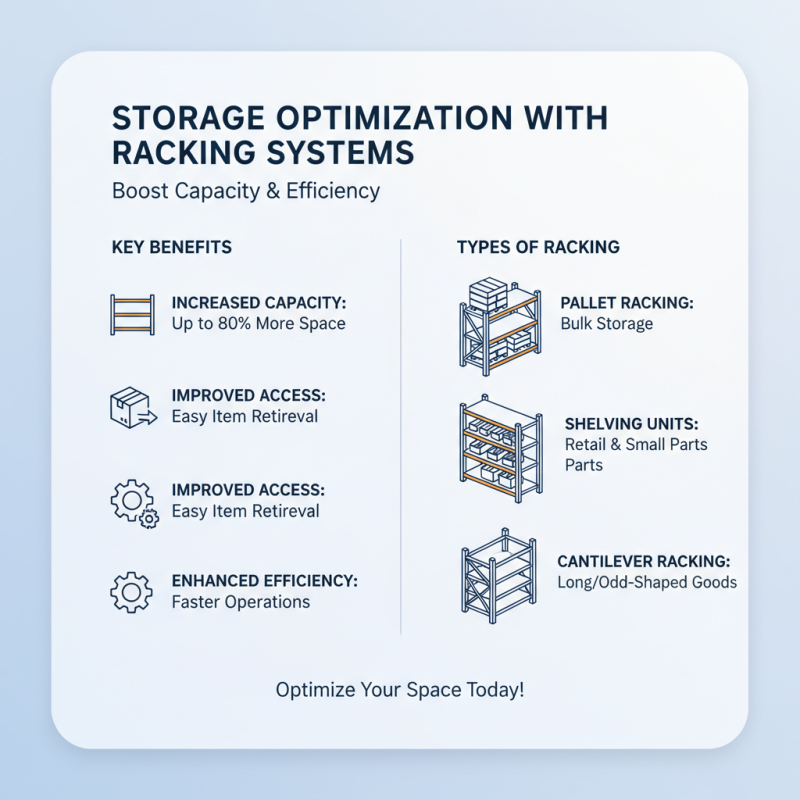

Racking systems are crucial for optimizing storage in warehouses and retail spaces. They come in various forms, each offering distinct advantages. For instance, pallet racking is ideal for bulk storage. It provides easy access to goods, enhancing operational efficiency. According to recent industry reports, businesses can boost storage capacity by up to 80% with properly implemented racking solutions.

Another popular option is shelving units. These are flexible and suitable for various products, from small parts to larger items. Adjustable shelving allows for the customization of height and space, catering to changing inventory needs. A study indicated that using adjustable shelves can improve workflow by 20% in busy environments. However, it’s vital to assess weight limits to prevent overloading.

**Tip:** Consider the layout of your space before selecting a racking system. Horizontal and vertical space can alter your storage game. Evaluate your inventory turnover rates to ensure the chosen system aligns with your operational needs. Different systems exhibit unique traits, making it essential to choose wisely, especially with limited budgets.

**Tip:** Regularly inspect and maintain your racking system. Poor maintenance can lead to safety hazards. It can also reduce efficiency over time. Simple adjustments can significantly improve functionality and longevity.

Key Features to Look for in Racking and Shelving Systems

When considering racking and shelving systems, prioritize flexibility. The ability to adjust shelves is crucial. This feature accommodates various items, from boxes to tools. A system that adapts makes storage easier and maximizes space. Consider adjustable shelving with a click system. It allows quick reorganizing.

Next, look for durability. Materials should withstand weight and time. Steel options often provide better strength. However, weight can be a concern with heavier loads. Keep safety in mind; unstable racks can lead to accidents. Additionally, the surface finish matters. A smooth finish can prevent scratches and potential injuries.

Finally, ease of access is key. Systems that allow easy reach reduce time spent searching. Think about adding wheels for mobile options. This can facilitate better organization. However, mobile systems may feel less sturdy. Reflect on your specific needs. Not every solution fits all situations. Balance convenience with stability for optimal results.

Top 10 Racking and Shelving Systems for Efficient Storage Solutions

| System Type | Key Features | Load Capacity (lbs) | Adjustability | Ideal Use |

|---|---|---|---|---|

| Boltless Shelving | Easy assembly, no tools required | 2,000 | 5 Levels | Warehouse Storage |

| Pallet Racking | Wide access, adjustable beam heights | 4,500 | Multiple Configuration Options | Industrial Warehousing |

| Cantilever Racking | Supports long items, open design | 3,000 | Fixed or Adjustable | Lumber and Pipe Storage |

| Flow Racking | FIFO system, gravity flow | 3,000 | Fixed | Retail and Distribution |

| Drive-In Racking | High-density storage, single aisle | 5,500 | Fixed | Bulk Storage Solutions |

| Mobile Shelving | Compact design, moves on tracks | Variable | Adjustable | Libraries and Archives |

| Wire Shelving | Ventilated design, modular | 1,000 | Adjustable | Retail and Storage |

| Shelf Bracket Systems | Customizable, various sizes | 1,500 | Fixed | Home or Office Use |

| Double Deep Racking | Increased storage density | 4,000 | Fixed | Pallet Storage |

| Vertical Racking | Space-saving design, height utilization | 2,500 | Adjustable | Compact Storage Areas |

Top 10 Racking Systems for Maximizing Warehouse Space Efficiency

Maximizing warehouse space efficiency is critical for businesses today. Data shows that well-organized storage can save up to 30% of floor space. This is where effective racking systems come into play. Different racking options can help warehouses utilize vertical space. For example, selective racking offers direct access to each pallet and is straightforward to manage.

Though it sounds ideal, selective racking has its limitations. It may not be the best choice for facilities with high inventory turnover. In contrast, drive-in racks can hold more inventory, but accessing specific items becomes challenging. Studies indicate that using multi-tier shelving increases utilization by about 40%. However, this can lead to a more complex picking process. Ongoing training is required to mitigate errors.

Moreover, adjustable shelving is versatile but can become cluttered if not organized properly. Implementing a systematic approach is vital. Visibility is often compromised in multi-level systems. Therefore, regular audits can help keep the process streamlined. As warehouses grow, these choices must be regularly reassessed. Stagnation in storage methods can hinder operational efficiency. Understanding the balance between space-saving and accessibility is crucial for long-term success.

Comparative Analysis of Cost-Effective Storage Solutions

Efficient storage solutions are essential for businesses seeking to optimize space and reduce costs. A recent report highlighted that ineffective storage can waste up to 30% of floor space. Choosing the right racking and shelving systems can significantly enhance organization and accessibility, thus improving overall productivity.

When analyzing cost-effective options, consider the layout of your space and the items stored. Adjustable shelving can adapt to various products. Mobile racking systems maximize space in smaller areas but can require higher initial investment. Understanding the long-term benefits is crucial, as flexibility often leads to better utilization.

Tips: Evaluate your inventory turnover to determine which systems suit your needs. Keep in mind that initial savings may not always translate to long-term efficiency. Regularly audit your storage systems to identify inefficiencies. Reinventing your storage layout can yield significant improvements but might demand a trial-and-error approach. Embrace the learning curve for long-lasting success.

Future Trends in Racking and Shelving Technology for Enhanced Storage

The future of racking and shelving technology is evolving rapidly. Innovative materials and designs are at the forefront. Light-weight metals and durable polymers are making systems more efficient. Users favor flexibility in their storage solutions. Adjustable shelving heights cater to various product sizes. This adaptability is key for dynamic inventory management.

Automation is another trend reshaping storage. Automated retrieval systems enhance speed and accuracy. Yet, these systems can be costly. Smaller businesses might struggle to justify the investment. Balancing automation and traditional methods is crucial. They both have their pros and cons. Finding the right mix can be challenging.

Sustainability is gaining importance, too. Eco-friendly materials reduce the environmental impact. However, not every business prioritizes sustainability in their operations. Companies must reflect on their choices. Incorporating sustainable practices in racking and shelving design can lead to long-term benefits. The journey to enhance storage solutions often comes with bumps. But the potential is significant if managed correctly.

Related Posts

-

2025 How to Optimize Your Warehouse with Commercial Racking Solutions

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

What are the Best Commercial Racking Systems for 2026?

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More