WSS Blog

Follow our latest updates and thoughts on our industryWhy Choose Pallet Racking in Brisbane for Your Warehouse Storage Needs

When it comes to optimizing warehouse storage solutions, selecting the right system is crucial for efficiency and cost-effectiveness. Among various storage options, pallet racking Brisbane stands out as a preferred choice for many businesses. According to a 2022 report by Logistics Management, the global warehouse management systems market is expected to reach $6 billion by 2025, highlighting the increasing demand for efficient storage methods like pallet racking. This robust system not only maximizes vertical space but also facilitates easier inventory management, allowing warehouses to adapt to ever-changing logistics needs.

Moreover, a study conducted by the Material Handling Industry (MHI) revealed that maximizing storage density can lead to a 30% increase in operational efficiency. This statistic is particularly relevant for warehouses in urban centers like Brisbane, where space is at a premium. Choosing pallet racking can effectively reduce clutter and streamline retrieval processes, thereby enhancing overall productivity. In a competitive market, investing in advanced storage solutions such as pallet racking Brisbane can provide a significant advantage, helping businesses to operate more efficiently and meet customer demands with precision.

Benefits of Pallet Racking for Efficient Warehouse Storage

Pallet racking systems are essential for efficient warehouse storage, especially in bustling areas like Brisbane. This type of storage solution maximizes vertical space, allowing warehouses to store more products without expanding their footprint. As warehouses face increasing pressures to optimize storage density, pallet racking proves to be the ideal choice. By utilizing heavy-duty racks, businesses can handle larger volumes of inventory safely and effectively, minimizing the risk of damage to both products and the racking systems.

Moreover, the benefits of pallet racking extend beyond mere space optimization. These systems improve inventory management by providing a structured way to access goods, which enhances workflow efficiency. With the rising demand for effective storage solutions driven by globalization, investing in pallet racking not only addresses immediate storage needs but also sets the groundwork for future growth and adaptability. As the market for pallet racking continues to expand, with projections indicating significant growth in the coming years, the importance of these systems in modern warehousing is clear.

Types of Pallet Racking Systems Available in Brisbane

Pallet racking systems provide an efficient and organized way to maximize storage space in your warehouse. In Brisbane, various types of pallet racking systems are available to cater to diverse storage needs. Among the most popular options are selective racking, drive-in racking, and cantilever racking. Selective racking is ideal for businesses that require quick access to individual pallets, as it allows easy loading and unloading. Drive-in racking maximizes space efficiency by allowing forklifts to enter the rack's aisles, making it suitable for high-density storage. On the other hand, cantilever racking is perfect for storing longer items, such as pipes or timber, thanks to its extended arms.

Pallet racking systems provide an efficient and organized way to maximize storage space in your warehouse. In Brisbane, various types of pallet racking systems are available to cater to diverse storage needs. Among the most popular options are selective racking, drive-in racking, and cantilever racking. Selective racking is ideal for businesses that require quick access to individual pallets, as it allows easy loading and unloading. Drive-in racking maximizes space efficiency by allowing forklifts to enter the rack's aisles, making it suitable for high-density storage. On the other hand, cantilever racking is perfect for storing longer items, such as pipes or timber, thanks to its extended arms.

When choosing a pallet racking system, it’s essential to consider the nature of your products and the frequency of access. Here are some tips: First, assess your inventory rotation—if you frequently move items in and out, selective racking may be your best option. Second, evaluate the height and weight of the items you plan to store; higher, heavier items may benefit from more robust racking systems. Finally, ensure compliance with safety regulations to avoid potential hazards in your warehouse environment. By carefully selecting the right pallet racking system, you can optimize your storage capacity and improve overall warehouse efficiency.

Key Considerations When Choosing Pallet Racking for Your Warehouse

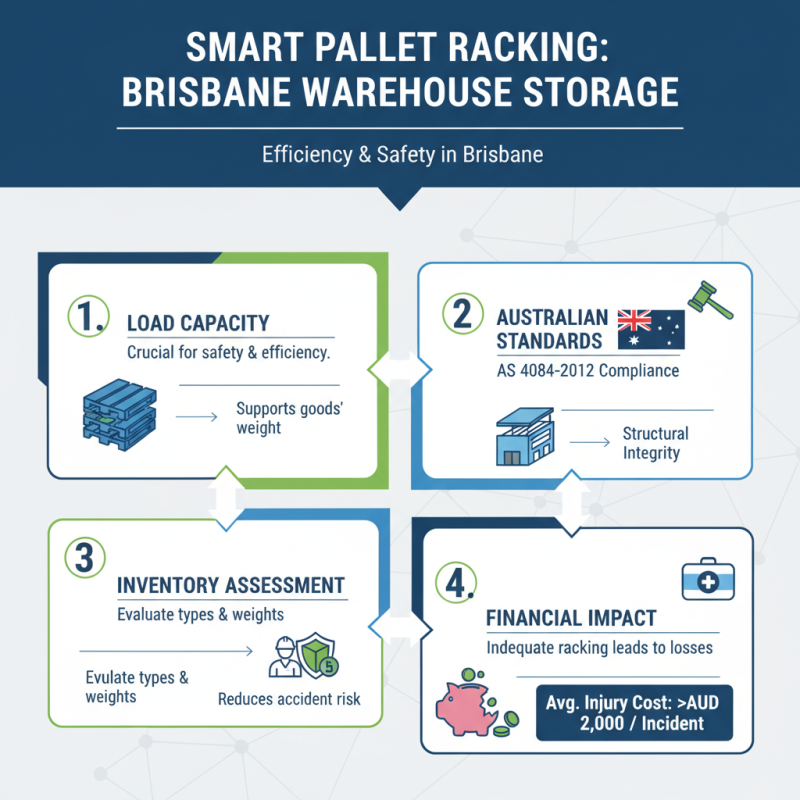

When selecting pallet racking for warehouse storage in Brisbane, it's crucial to consider several key factors that impact efficiency and safety. One of the most critical aspects is the load capacity of the racking system. According to the Australian Standards AS 4084-2012, pallet racking must be designed to adequately support the weight of stacked goods without compromising structural integrity. Businesses should evaluate their inventory types and weights, as studies indicate that inadequate racking can lead to accidents, resulting in significant financial losses, with the average cost of warehouse-related injuries reaching over AUD 20,000 per incident.

Another important consideration is the warehouse layout and available space. Industry reports suggest that optimizing vertical space can increase storage capacity by up to 50%, which is particularly beneficial in urban settings where real estate is costly. Therefore, businesses in Brisbane should look into systems that maximize vertical storage while ensuring compliance with safety regulations. Additionally, it is recommended to choose adjustable racking systems, allowing for flexibility to accommodate future inventory changes. This adaptability can ultimately lead to improved operational efficiency, reducing overhead costs and enhancing overall profitability in competitive markets.

Installation and Maintenance of Pallet Racking Systems

When considering pallet racking systems for your warehouse in Brisbane, installation and maintenance are crucial elements that can significantly impact efficiency and safety. Proper installation begins with a thorough assessment of the warehouse layout and inventory needs. This involves selecting the right type of pallet racking suitable for your goods, whether it be selective, drive-in, or push-back racking. Experienced professionals should conduct the installation to ensure that the racks are securely anchored and comply with safety regulations. This not only maximizes storage capacity but also minimizes the risk of accidents during warehouse operations.

Maintenance of pallet racking systems is equally important to extend their lifespan and ensure safety. Regular inspections should be conducted to check for signs of wear and tear, such as bent frames or damaged beams. It’s advisable to implement a routine maintenance schedule that includes cleaning the racks, tightening bolts, and addressing any safety concerns promptly. Additionally, training staff on proper loading techniques can prevent undue stress on the racking systems. By prioritizing installation and maintenance, businesses in Brisbane can optimize their warehouse storage solutions while safeguarding their operations.

Why Choose Pallet Racking in Brisbane for Your Warehouse Storage Needs - Installation and Maintenance of Pallet Racking Systems

| Dimension | Details |

|---|---|

| Type of Pallet Racking | Selective, Drive-In, Push Back, Mobile, Double-Deep |

| Load Capacity | Up to 3000 kg per level |

| Frame Height | From 1.5 meters to 9 meters |

| Installation Time | 1 to 3 days depending on size |

| Maintenance Frequency | Annual inspections recommended |

| Safety Standards | Complies with Australian Safety Standards (AS 4084) |

| Benefits | Maximized storage space, easy access, increased organization |

Cost-Effectiveness of Pallet Racking Compared to Other Storage Solutions

Pallet racking systems have emerged as a leading storage solution for warehouses in Brisbane, primarily due to their cost-effectiveness when compared to alternative storage methods. Unlike traditional shelving units or static racks, pallet racking allows for the vertical storage of goods, maximizing the use of available space. This not only reduces the square footage required but also lowers overhead costs associated with leasing larger facilities. By utilizing vertical space efficiently, businesses can store more inventory without the need for significant capital investment in additional storage areas.

Moreover, pallet racking systems can be easily customized and adjusted to suit varying product sizes and inventory needs. This flexibility helps warehouse operators avoid unnecessary expenditures on inflexible storage solutions that may become obsolete. Additionally, the durability and longevity of pallet racking materials mean lower maintenance and replacement costs over time. When considering the overall return on investment, pallet racking stands out as a financially savvy choice for warehouses aiming to optimize storage and improve operational efficiency.

Cost-Effectiveness of Pallet Racking Compared to Other Storage Solutions

Related Posts

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More