WSS Blog

Follow our latest updates and thoughts on our industry2025 How to Optimize Your Warehouse with Commercial Racking Solutions

In the ever-evolving landscape of logistics and supply chain management, optimizing warehouse space is more crucial than ever. According to a report by the Warehousing Education and Research Council, an effective warehouse can reduce operational costs by up to 30%. One of the most impactful strategies for achieving this optimization is through the implementation of commercial racking solutions. These systems not only enhance storage capacity but also improve accessibility and workflow efficiency, ultimately leading to increased productivity.

Statistics from the Material Handling Industry indicate that warehouses utilizing advanced racking systems can achieve a space utilization increase of 50% or more. This is particularly important in industries where real estate costs are soaring and efficient space management is paramount. With the rise of e-commerce and consumer demand for quick turnaround times, businesses are under pressure to maximize every square foot. Utilizing commercial racking not only addresses space constraints but also facilitates an organized, systematic approach to inventory management that can significantly enhance overall operational performance.

As we look toward 2025, the emphasis on integrating innovative commercial racking solutions in warehouse design will be essential for businesses aiming to stay competitive in a crowded marketplace. Implementing these systems strategically can lead to better inventory control, reduced picking times, and ultimately, greater customer satisfaction.

Understanding the Importance of Efficient Warehouse Racking Systems

Efficient warehouse racking systems are crucial for optimizing storage and enhancing operational productivity. According to a report by the Warehousing Education and Research Council (WERC), organizations can improve their space utilization by up to 30% through the implementation of strategically designed racking solutions. These systems not only maximize vertical space but also facilitate better organization of inventory, which can significantly reduce retrieval times. With the global warehouse automation market anticipated to reach $30 billion by 2026, the role of effective racking becomes even more critical as businesses seek to integrate technology into their logistics frameworks.

Moreover, the right racking solutions can lead to substantial cost savings. A study by MHI reveals that proper racking can decrease labor costs by up to 20% as a result of improved accessibility and workflow efficiencies. This is particularly important as labor represents one of the largest expenses in warehouse operations. Implementing customizable racking solutions tailored to specific inventory types allows businesses to adjust to changing market demands while enhancing their overall operational agility. As the e-commerce sector continues to grow, warehouses must adapt by investing in innovative racking systems that can support rapid inventory turnover and streamlined order fulfillment processes.

Key Types of Commercial Racking Solutions and Their Applications

When seeking to optimize warehouse efficiency, understanding the various types of commercial racking solutions is paramount. Among the most popular options is the selective pallet racking system, which allows for easy access to individual pallets, making it ideal for warehouses that handle a wide variety of products at different turnover rates. By maximizing vertical space and providing straightforward retrieval, selective racking ensures that inventory management is both efficient and flexible.

Another effective solution is the drive-in/rack system, which maximizes storage density by enabling pallet storage on a first-in, last-out basis. This setup is particularly beneficial for businesses with large quantities of similar products that are stored in bulk. Additionally, there are gravity flow racks, designed to utilize the basic principles of gravity to move product through the racking system, allowing for a highly efficient and effective method of inventory rotation. Each type of racking solution serves specific needs and applications, enabling warehouse managers to tailor their storage strategies accordingly and ultimately enhance overall operational effectiveness.

2025 How to Optimize Your Warehouse with Commercial Racking Solutions - Key Types of Commercial Racking Solutions and Their Applications

| Racking Type | Description | Applications | Weight Capacity |

|---|---|---|---|

| Selective Racking | Standard racking system with adjustable shelving | General warehouse storage, light to medium products | Up to 3,000 lbs per level |

| Drive-In Racking | Compact back-to-back pallet storage for high-density inventory | Bulk product storage, low SKU variety | Up to 4,000 lbs per pallet |

| Push Back Racking | Supplies FIFO access and maximizes depth | Food distribution, beverage, and durable goods | Up to 2,000 lbs per pallet |

| Cantilever Racking | Ideal for storing long or bulky items | Lumber yards, metal service centers, furniture | Up to 7,000 lbs per arm |

| Mobile Racking | Racking on moving bases to optimize space | Cold storage warehouses, high-density storage | Varies based on configuration |

Maximizing Space Utilization: Vertical Storage and Racking Techniques

Maximizing space utilization in warehouses is essential for enhancing operational efficiency and reducing costs. According to a report by the Warehouse Optimization Research Group, effective use of vertical storage can increase a warehouse's storage capacity by up to 30%. This increase is largely attributable to the incorporation of commercial racking systems that enable businesses to utilize the vertical space that often goes unutilized. For instance, pallet racking allows for the stacking of goods upwards rather than outwards, which not only maximizes floor space but also makes inventory management more streamlined.

Vertical storage solutions, including narrow aisle racking and cantilever racks, play a crucial role in optimizing warehouse operations. By implementing these techniques, companies can reduce the footprint of their storage systems while improving access to products. The National Institute of Warehouse Management has reported that vertical solutions can decrease travel time and increase picking speed by up to 40%, leading to higher throughput and improved customer satisfaction. Furthermore, investing in modern racking systems can lead to safer working environments, as they often come with updated safety features and more organized storage that minimizes accidents and damages.

Warehouse Space Utilization Optimization (2025)

This chart illustrates the effectiveness of various commercial racking solutions in maximizing warehouse space utilization. The data compares the available storage space before and after implementing these solutions.

Impact of Warehouse Racking on Supply Chain Efficiency Metrics

Warehouse racking solutions play a crucial role in enhancing supply chain efficiency metrics. By optimizing storage space, racking systems allow for better organization and accessibility of inventory. This configuration not only maximizes vertical space but also reduces the time and effort required for picking and restocking items. Efficient racking solutions streamline workflow processes, enabling quicker turnover rates and improved order fulfillment times. Consequently, companies can respond more rapidly to market demands, which is essential in today's fast-paced business environment.

Moreover, the implementation of tailored racking solutions can significantly affect key performance indicators (KPIs) such as inventory accuracy and order accuracy rates. Well-designed racking methods support effective inventory management practices, allowing for easier tracking of stock levels and rotation. This minimizes the risk of overstocking or stockouts, which can lead to increased costs and customer dissatisfaction. By focusing on optimizing warehouse layout and making strategic decisions about racking, businesses can enhance their overall logistical efficiency and drive a more agile supply chain, ultimately contributing to improved operational performance and customer service.

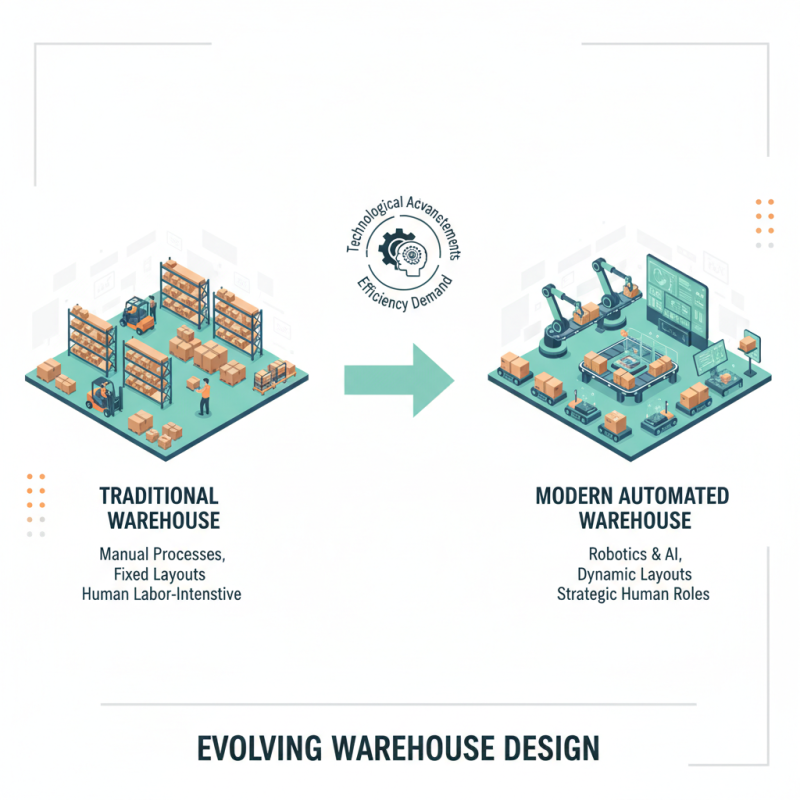

Future Trends in Warehouse Design: Automation and Modular Racking Systems

The landscape of warehouse design is evolving rapidly, driven by advancements in technology and a growing demand for efficiency. Automation is at the forefront, with many warehouses adopting robotic systems and AI-driven inventory management tools. These technological innovations not only enhance productivity but also free up human resources for more strategic tasks. As warehouses transition to more automated systems, the layout must accommodate these changes, enabling smooth workflows and minimizing bottlenecks.

Modular racking systems are becoming increasingly popular, allowing for flexible storage solutions that can adapt to changing inventory needs. These systems can be easily reconfigured or expanded, making them ideal for businesses looking to scale operations or diversify product lines. Additionally, modular racking enhances space utilization, maximizing storage capacity and improving accessibility.

**Tips**: When designing your warehouse, consider incorporating adjustable racking systems that allow for easy modifications as inventory types and volumes shift. Additionally, invest in automation tools that integrate seamlessly with your existing infrastructure; this ensures a smoother transition and minimizes disruption during implementation. Lastly, keep future scalability in mind by choosing designs that accommodate both current and potential operational needs.

Related Posts

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More