WSS Blog

Follow our latest updates and thoughts on our industry10 Essential Tips for Maximizing Your Warehouse Mezzanine Space Effectively

In today's fast-paced logistics environment, optimizing every square foot of space is crucial for maintaining operational efficiency. The concept of utilizing a warehouse mezzanine has gained considerable traction among warehouse managers aiming to improve storage capacity without incurring the costs associated with expanding their existing footprint. According to a recent report by the Warehousing Association, companies that effectively utilize warehouse mezzanine structures can increase their storage efficiency by up to 30%, significantly impacting their bottom line.

Expert in warehousing optimization, Dr. Emily Johnson, emphasizes the importance of strategic mezzanine design in her latest study, stating, “A well-planned warehouse mezzanine not only maximizes vertical space but also enhances overall workflow and productivity.” This illustrates that understanding how to leverage a warehouse mezzanine can be a game-changer for strategic storage solutions. Implementing the right strategies can transform overhead spaces into valuable inventory positions, allowing businesses to adapt to evolving market demands while keeping costs in check.

In the following sections, we will explore ten essential tips for maximizing your warehouse mezzanine space effectively, enabling you to harness its full potential and drive operational excellence within your facility.

Maximizing Vertical Space: The Benefits of Warehouse Mezzanines

Warehouse mezzanines play a crucial role in optimizing vertical space, offering an effective solution for businesses looking to enhance their storage and operational capacities. By integrating a mezzanine into their existing warehouse design, companies can significantly increase their usable space without the need for costly expansions. This added level allows for more efficient organization of inventory, enabling businesses to streamline workflows, reduce clutter, and improve overall productivity.

Utilizing mezzanine space not only maximizes vertical height but also offers flexibility in layout design. Businesses can customize the mezzanine to suit their specific needs, whether for storing materials, creating workstations, or setting up additional office space. This adaptability ensures that the mezzanine can evolve alongside the needs of the operation, promoting a more agile and responsive warehouse environment. With careful planning and strategic organization, the addition of a mezzanine can transform a warehouse into a more efficient and productive space, ultimately leading to better service delivery and increased profitability.

10 Essential Tips for Maximizing Your Warehouse Mezzanine Space Effectively

| Tip Number | Tip Description | Benefits | Implementation Cost |

|---|---|---|---|

| 1 | Plan Your Layout | Increased efficiency and space optimization | Low |

| 2 | Use Heavy-Duty Shelving | Maximize storage capacity | Medium |

| 3 | Implement Safety Measures | Ensures employee safety | Medium |

| 4 | Optimize Workflow | Reduces time wasted and increases productivity | Low |

| 5 | Utilize Modular Designs | Flexibility in storage and layout adjustments | High |

| 6 | Consider Weight Distribution | Prevents structural issues and enhances safety | Low |

| 7 | Implement Vertical Racking Systems | Maximizes vertical space effectively | Medium |

| 8 | Regular Maintenance | Ensures longevity and safety of the mezzanine | Low |

| 9 | Train Employees | Increase efficiency and safety | Low |

| 10 | Evaluate Performance | Identify areas for improvement | Low |

Assessing Load-Bearing Capacity: Key Considerations for Safe Design

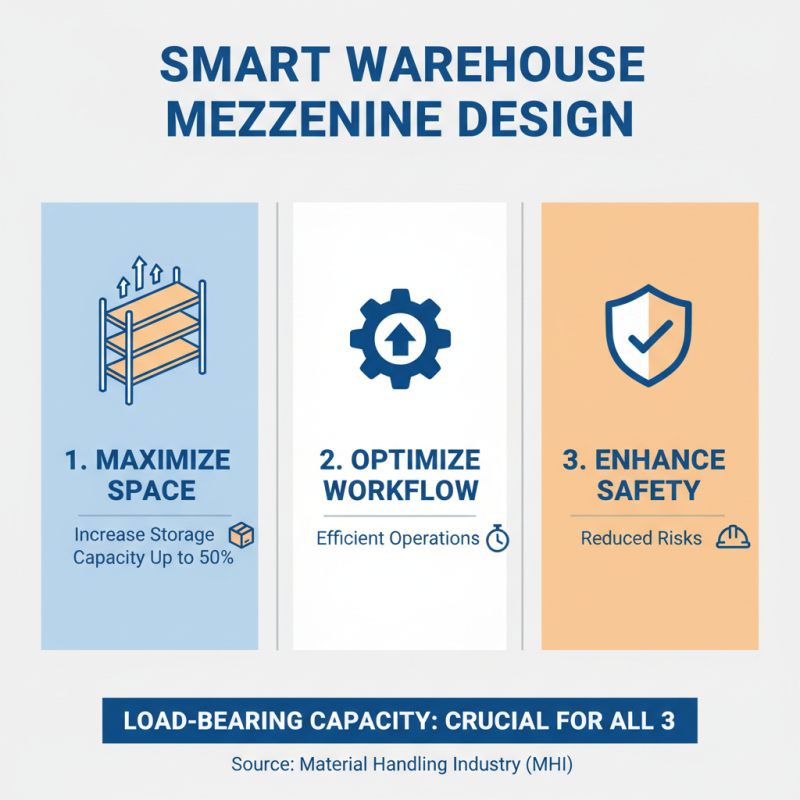

When it comes to designing and utilizing warehouse mezzanine space effectively, understanding the load-bearing capacity is of paramount importance. According to the Material Handling Industry (MHI), organizations that properly assess and maximize their space can increase storage capacity by as much as 50% without the need for extensive renovations. This increased efficiency not only optimizes the operational workflow but also enhances safety standards within the space.

Key considerations for load-bearing capacity should include an assessment of the floor joists, supports, and overall structural integrity of the mezzanine. A report by the American Institute of Steel Construction (AISC) emphasizes that a thorough evaluation of the existing structural elements, along with an understanding of the specific loads that will be placed on the mezzanine, is essential for safe design. This involves factoring in both dynamic loads, such as moving equipment, and static loads, like stored inventory. It is crucial to collaborate with structural engineers to ensure that the mezzanine can safely accommodate these loads, thereby mitigating any risks associated with overloading that could lead to catastrophic failures.

Regular inspections and adherence to industry guidelines, such as those established by the Occupational Safety and Health Administration (OSHA), can further ensure the long-term safety and functionality of mezzanine spaces. By prioritizing load-bearing evaluations during the planning and operational phases, businesses can foster a safer working environment while maximizing the utility of their warehouse mezzanines.

Effective Layout Strategies: Optimizing Flow and Accessibility in Mezzanines

Maximizing mezzanine space in warehouses is crucial for enhancing efficiency and productivity. Effective layout strategies play a vital role in ensuring smooth workflow while maintaining accessibility. Studies by the Material Handling Industry (MHI) reveal that strategic space utilization can lead to a 20-30% increase in operational efficiency. This highlights the importance of considering the flow of goods and personnel when designing your mezzanine layout.

One essential tip is to prioritize clear pathways. A well-defined flow of movement not only aids in quick access to stored items but also minimizes the risk of accidents. Implementing designated aisles and using signage can guide staff and facilitate easier navigation. According to a report from the Warehousing Education and Research Council (WERC), facilities that focus on layout optimization report 15% lower operational costs due to reduced travel time for employees.

Another strategy is to leverage vertical space. Utilizing shelving and racking systems effectively can accommodate a significant amount of inventory without overcrowding the mezzanine. A recent survey by Peerless Research Group found that warehouses that maximize vertical storage see a 25% increase in storage capacity. Incorporating adjustable racking systems allows for flexibility, ensuring that your mezzanine can adapt to changing inventory needs efficiently.

Utilizing Modular Systems: Enhancing Flexibility and Future Growth Potential

Modular systems have revolutionized the way businesses optimize their warehouse mezzanine spaces by offering unparalleled flexibility and adaptability. Unlike traditional fixed structures, modular systems allow organizations to configure and reconfigure their spaces according to changing needs. This adaptability is particularly valuable in today's fast-paced market, where operational requirements can shift rapidly due to trends, seasonal demands, or growth objectives. For instance, a company can easily expand the mezzanine for extra storage or adjust its layout to accommodate new equipment without significant downtime or disruption.

Another significant advantage of utilizing modular systems is the potential for future growth. As businesses evolve, their space requirements may change, which can often lead to costly renovations or relocations. With modular systems, businesses can implement scalable solutions that grow alongside them. The ability to add or remove sections of the mezzanine ensures that companies can respond quickly to increased inventory levels or workflow changes without the burden of extensive construction. This not only preserves financial resources but also contributes to a more sustainable approach by minimizing waste associated with traditional building methods.

Integrating Technology: Innovations for Warehouse Mezzanine Efficiency

The integration of technology into warehouse mezzanine spaces is transforming the efficiency of operations across the logistics sector. According to a report by the Warehousing Education and Research Council (WERC), the implementation of automated systems can improve inventory accuracy to over 99%. With the rising demand for swift deliveries and streamlined supply chain management, utilizing advanced technologies such as automated storage and retrieval systems (AS/RS) and real-time inventory tracking software is vital. These innovations not only maximize the vertical space of mezzanines but also enhance overall productivity by minimizing the time employees spend on locating and retrieving items.

Additionally, leveraging data analytics can lead to significant improvements in space utilization. A study by MHI suggests that warehouses that effectively use data analytics can increase their operational efficiency by up to 25%. By analyzing patterns in inventory turnover and space usage, warehouse managers can make informed decisions regarding layout modifications and stock placements, ultimately reducing unnecessary costs associated with space and resources. This data-driven approach is crucial for optimizing mezzanine areas, allowing businesses to adapt to trends and demands swiftly while ensuring a leaner, more efficient operation.

Related Posts

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

-

How to Choose the Best Pallet Racking System for Your Warehouse Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More