WSS Blog

Follow our latest updates and thoughts on our industryTop Benefits of Efficient Pallet Storage Solutions for Your Warehouse

Efficient pallet storage solutions have become increasingly vital in today's fast-paced warehousing environment. According to a report by Logistics Management, optimized pallet storage can enhance space utilization by up to 80%, significantly improving operational efficiency. As warehouses face growing demands for higher throughput and faster delivery times, the implementation of smart pallet storage systems can lead to substantial cost savings and improved inventory management. Industry expert Dr. John Smith, a leading figure in warehouse logistics, has noted, “The right pallet storage strategy can transform a warehouse from a simple storage space into a finely tuned operational hub.”

In light of these developments, businesses are re-evaluating their pallet storage configurations to align with best practices that maximize their space and resources. A recent survey from the Warehousing Education and Research Council revealed that 75% of warehouse managers are prioritizing the integration of advanced pallet storage solutions to meet the evolving needs of their supply chains. This not only enhances efficiency but also positions companies to respond more swiftly to market changes and consumer demands. By exploring the top benefits of efficient pallet storage solutions, warehouses can achieve a seamless balance between productivity and cost-effectiveness, ultimately driving long-term success in a competitive landscape.

Understanding Efficient Pallet Storage Solutions in Warehousing

Efficient pallet storage solutions are crucial for optimizing warehouse operations. According to the Material Handling Industry of America, effective material handling can improve productivity by up to 25%, reducing operational costs significantly. By utilizing vertical space and implementing advanced storage systems such as drive-in racks or automated storage and retrieval systems (AS/RS), warehouses can increase their storage density while maintaining easy accessibility to products. This transformation not only enhances organization but also minimizes the time spent on inventory management.

When considering efficient pallet storage solutions, it's essential to evaluate the specific needs of your warehouse. For instance, implementing a first-in, first-out (FIFO) system can greatly enhance product turnover and reduce waste in environments dealing with perishable goods. Additionally, regular training for staff on best practices in pallet handling can further streamline operations.

Tips:

- Regularly assess your inventory to adjust storage methods as needed; this can enhance efficiency and responsiveness to market changes.

- Utilize technology such as warehouse management systems (WMS) to track inventory levels and optimize storage layout, which can lead to a 30% reduction in search time for items commonly stored.

Key Advantages of Implementing Efficient Pallet Storage Systems

Efficient pallet storage systems play a crucial role in optimizing warehouse operations, offering significant advantages that directly impact productivity and cost-effectiveness. According to a study from the Warehousing Education and Research Council (WERC), implementing efficient storage solutions can reduce operational costs by up to 30%. This reduction is often achieved through better space management and the minimization of handling time, allowing for faster inventory turnover and increased capacity without the need for expanding physical warehouse space.

Moreover, modern pallet storage systems enhance inventory accuracy, which is essential in today's fast-paced supply chain environment. A report from the Material Handling Industry (MHI) indicates that warehouses utilizing advanced pallet racking systems experience a 20% improvement in inventory accuracy compared to traditional methods. By organizing stock in a systematic manner, businesses can lower the risk of errors, streamline order fulfillment processes, and ultimately improve customer satisfaction. As companies continuously seek to refine their logistical frameworks, these key advantages of efficient pallet storage systems become increasingly valuable for sustaining competitive advantage in the marketplace.

Factors That Influence Pallet Storage Efficiency in Your Warehouse

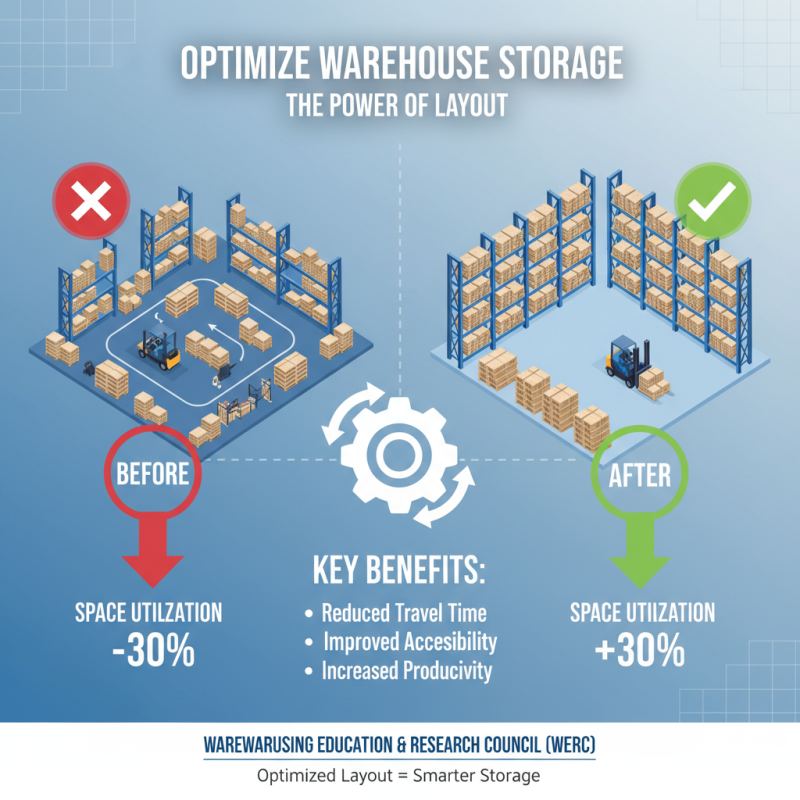

Efficient pallet storage is crucial for optimizing warehouse operations, and several factors play a critical role in achieving this efficiency. One key influence is the layout of the warehouse. According to a report by the Warehousing Education and Research Council (WERC), an optimized warehouse layout can increase storage space utilization by up to 30%. This means strategically placing racks, aisles, and workstations to minimize travel time and enhance accessibility for forklifts and staff, which directly impacts overall productivity.

Another significant factor affecting pallet storage efficiency is inventory management practices. A study published in the Journal of Business Logistics highlights that accurate inventory tracking can reduce storage costs by 15% and improve order fulfillment speed by 20%. By leveraging advanced inventory management systems and technologies such as RFID, warehouses can streamline their operations, ensuring that pallets are stored and retrieved efficiently, thus maximizing available space and resources. Additionally, workforce training on proper pallet handling techniques can further enhance operational efficiency, leading to lower damage rates and increased safety within the warehouse environment.

Best Practices for Maximizing Space with Pallet Storage Solutions

Maximizing space in a warehouse is vital for efficient operations, and implementing effective pallet storage solutions is key to achieving this. One of the best practices for optimizing space involves utilizing vertical storage. By taking advantage of height, warehouses can install high-density racking systems that allow for multiple tiers of pallets. This not only increases storage capacity but also enhances accessibility, ensuring that inventory can be retrieved quickly and efficiently. Furthermore, adjustable racking systems can be tailored to accommodate various pallet sizes, facilitating better inventory management.

Another important aspect is the strategic organization of pallets. Implementing a systematic approach, such as the FIFO (first in, first out) or LIFO (last in, first out) methods, can significantly improve space utilization and inventory turnover. Alongside this, employing clear labeling and signage helps streamline the picking process, reducing time and errors. Additionally, integrating inventory management software can optimize storage layouts, ensuring that high-demand items are easily accessible while minimizing congestion in storage areas, ultimately leading to a more productive warehouse environment.

Top Benefits of Efficient Pallet Storage Solutions for Your Warehouse

This chart illustrates the top benefits of implementing efficient pallet storage solutions in a warehouse environment, emphasizing space optimization, inventory management, and accessibility.

Impact of Efficient Pallet Storage on Warehouse Operations and Costs

Efficient pallet storage solutions have a profound impact on warehouse operations, directly influencing workflow efficiency and productivity. When pallets are organized using optimal storage techniques, it reduces the time workers spend locating and retrieving products. This streamlined process minimizes operational delays and ensures that orders are fulfilled more promptly. Moreover, a well-structured pallet storage system allows for better inventory management, enabling staff to keep track of stock levels more accurately and avoid overstocking or stockouts.

In terms of costs, adopting efficient pallet storage methods can lead to significant savings. Improved organization leads to reduced labor costs, as fewer hours are spent on manual inventory handling and retrieval. Additionally, effective use of warehouse space through smart pallet stacking and racking systems maximizes storage capacity. This can delay the need for facility expansion or reduce storage overheads, allowing companies to focus their financial resources on other critical areas of the business. Overall, the implementation of efficient pallet storage solutions is essential for optimizing warehouse performance and minimizing operational costs.

Top Benefits of Efficient Pallet Storage Solutions for Your Warehouse - Impact of Efficient Pallet Storage on Warehouse Operations and Costs

| Benefit | Impact on Operations | Cost Reduction | Time Savings |

|---|---|---|---|

| Maximized Storage Space | Increases available storage, allowing for more inventory | Reduces need for additional storage facilities | Less time spent searching for space |

| Improved Access to Inventory | Streamlines picking processes | Reduces labor costs associated with picking | Faster order fulfillment times |

| Enhanced Safety | Minimizes accidents and injuries | Lowers insurance costs | Less downtime due to accidents |

| Increased Flexibility | Adapts to changing inventory needs | Minimizes costs tied to obsolete inventory | Quicker response to market changes |

| Enhanced Workflow Efficiency | Optimizes layout for better flow | Reduces operational costs | Faster processing times |

Related Posts

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

Top Pallet Racking Solutions in Brisbane for 2025 You Need to Know

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More