WSS Blog

Follow our latest updates and thoughts on our industryUltimate Guide to Dexion Pallet Racking Solutions for Your Warehouse

When it comes to optimizing warehouse space and improving operational efficiency, the right storage solutions are crucial. Among the myriad of options available, Dexion pallet racking stands out as a versatile and reliable choice for businesses looking to maximize their storage capabilities. This ultimate guide aims to provide warehouse managers and operators with comprehensive insights into Dexion pallet racking solutions, focusing on their benefits, features, and applications.

Dexion pallet racking systems are designed to accommodate a wide range of items, from small products to large pallets, making them suitable for various industries. Their robust construction ensures durability while facilitating easy access to stored products, thus enhancing the overall workflow of warehouse operations. In this guide, we will explore different types of Dexion pallet racking configurations, how to choose the right system for your needs, and tips for effective installation and maintenance.

Whether you are upgrading your existing storage setup or starting a new warehouse project, understanding the advantages of Dexion pallet racking is essential. By implementing these systems, you not only improve space utilization but also create a more organized and efficient working environment, ultimately contributing to the success of your business.

Understanding Dexion Pallet Racking: An Overview of Key Features

Dexion pallet racking systems are designed to optimize warehouse storage and enhance operational efficiency. One of the key features of these systems is their modular design, allowing for various configurations that accommodate different types of inventory and warehouse layouts. With an emphasis on flexibility, these racking solutions can be tailored to suit specific requirements, whether it's for large bulk items or small retail products. This adaptability not only maximizes storage density but also ensures that the racking can evolve alongside changing business needs.

Another significant aspect of Dexion pallet racking is its robust construction, which ensures safety and durability. The materials used in these systems are engineered to withstand considerable weight and stress, making them ideal for high-volume warehouses. Additionally, safety features such as integrated safety fences and the option for customized load labels contribute to a secure working environment. This focus on safety paired with ease of access allows warehouse staff to efficiently manage inventory, further streamlining operations.

Types of Dexion Pallet Racking Systems: A Comprehensive Comparison

When choosing the right Dexion pallet racking system for your warehouse, it's essential to understand the various types available to ensure maximum efficiency and safety. The three primary types of pallet racking systems include selective racking, drive-in racking, and flow racking. Selective racking is the most common, providing easy access to each pallet, making it ideal for facilities with a high variety of SKUs. According to industry reports, up to 80% of warehouses utilize selective racking due to its ability to maximize space while maintaining quick access to products.

Drive-in racking, on the other hand, is designed for high-density storage. This system allows multiple pallets to be stored in a single lane, utilizing a first-in, last-out (FILO) method. Research suggests that this system can increase storage capacity by 40%, making it ideal for warehouses with large quantities of similar items. Lastly, flow racking operates on the first-in, first-out (FIFO) principle, to ensure that older stock is used first, reducing spoilage. This system is particularly beneficial in industries with perishable goods or items that need to be rotated frequently.

**Tips:** When selecting a pallet racking system, consider conducting a warehouse audit to identify your storage needs and space limitations. Additionally, invest in proper training for your warehouse staff to maximize the efficiency and safety of your chosen systems. Regular maintenance and inspections are also vital to ensure the longevity of your racking solutions.

Ultimate Guide to Dexion Pallet Racking Solutions: Types Comparison

Installation and Safety Considerations for Dexion Pallet Racking

When installing pallet racking in a warehouse, safety should be the foremost consideration. Proper installation not only ensures maximum efficiency in storage but also minimizes the risk of accidents. Before starting the installation process, it’s crucial to assess the warehouse's layout and determine the intended load capacities. This includes evaluating the floor condition, available space, and the specific needs of your operations. By adhering to recommended load limits and ensuring uniform weight distribution across the racks, you can prevent potential collapses or damage.

In addition to the initial installation, ongoing safety measures are equally important. Regular inspections of the racking system are necessary to identify signs of wear and tear, misalignment, or structural damage. Providing training for employees on the safe handling of products when placing and retrieving items from the racking can significantly reduce hazards in the workplace. Moreover, implementing clear signage and protocols for usage can help maintain safety standards and ensure compliance with best practices. Being proactive about safety in pallet racking systems fosters a secure working environment, protecting both personnel and inventory.

Ultimate Guide to Dexion Pallet Racking Solutions for Your Warehouse

| Dimension | Details |

|---|---|

| Rack Height | From 8 to 30 feet |

| Beam Levels | 2 to 6 levels |

| Load Capacity | Up to 5,000 lbs per beam |

| Material | Steel, high-strength and durable |

| Safety Features | Safety pins, vertical brace protection |

| Installation Time | 1-2 days depending on size |

| Maintenance Frequency | Every 6 months |

| Common Uses | Storage, warehousing, distribution |

Maximizing Warehouse Space Efficiency with Dexion Solutions

Maximizing warehouse space efficiency is a crucial aspect of effective inventory management, and pallet racking solutions play a key role in achieving this goal. By implementing strategic racking systems, warehouses can utilize vertical space to its fullest potential, allowing for more product storage without the need for expansive floor areas.

Adjustable shelving and modular designs enable warehouses to adapt their layout to meet changing demands, ensuring that both small and large items can be stored efficiently.

In addition to optimizing space, a well-designed pallet racking system can improve accessibility and organization within the warehouse. By categorizing products and creating designated spaces for each item, warehouses can significantly reduce the time spent locating and retrieving goods. This not only enhances operational efficiency but also minimizes the risk of errors and damage to products.

Furthermore, investing in high-quality racking solutions can contribute to workplace safety by providing stable and secure storage arrangements, reducing the likelihood of accidents caused by cluttered aisles or improperly stored items.

Maintenance and Upgrades for Long-lasting Dexion Pallet Racking Systems

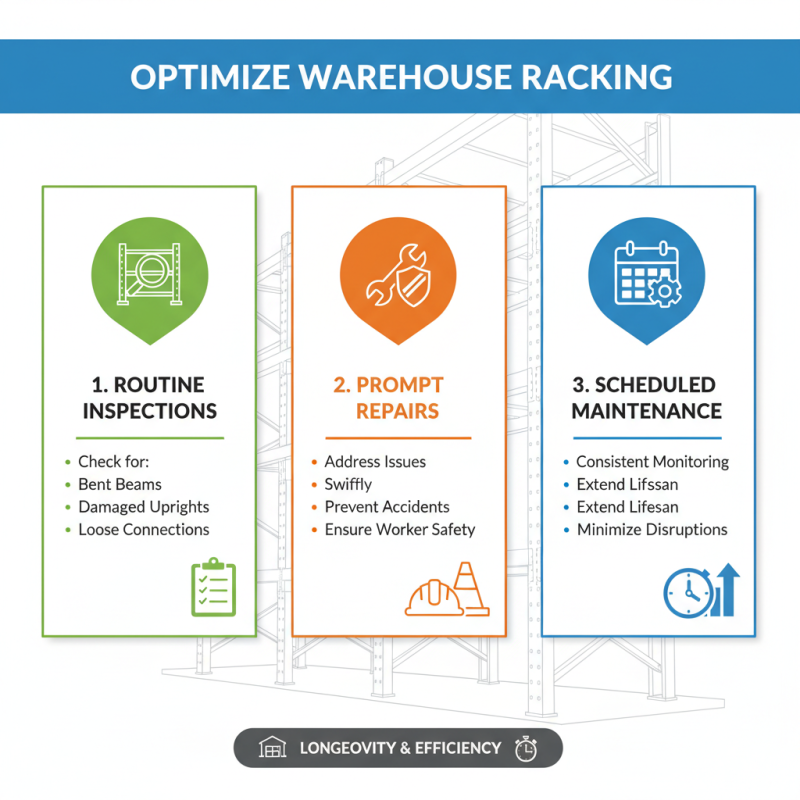

Maintaining and upgrading pallet racking systems is crucial for ensuring the longevity and efficiency of your warehouse operations. Regular inspections should be conducted to identify any signs of wear and tear, including bent beams, damaged uprights, or loose connections. By addressing these issues promptly, you can prevent accidents and ensure the safety of your workers. Implementing a routine maintenance schedule allows for consistent monitoring, which can help extend the lifespan of your racking systems and minimize operational disruptions.

Upgrades are equally important in keeping your warehouse adaptable and efficient. As your inventory needs evolve, you may require additional shelving or reconfiguration of existing systems to optimize space utilization. Investing in more advanced racking solutions, such as adjustable systems or automated options, can dramatically improve workflow and overall productivity. It's also beneficial to consider integrating safety features during upgrades, such as protective barriers and safety locks, to further enhance the reliability of your racking systems. Prioritizing maintenance and timely upgrades will ensure your pallet racking continues to support your business effectively for years to come.

Related Posts

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

-

Why You Should Choose Dexion Pallet Racking for Efficient Warehouse Storage

-

How to Choose the Best Pallet Racking System for Your Warehouse Needs

-

What is Pallet Shelving and How Can It Optimize Your Storage Solutions

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More