WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Warehouse Storage Racks for Your Business Needs

When it comes to optimizing space and efficiency in a warehouse, choosing the right warehouse storage racks is crucial. According to logistics expert John Thompson, “The appropriate selection of storage racks can significantly streamline operations and enhance productivity in any warehouse setting.” A well-organized warehouse not only helps in managing inventory effectively but also impacts the overall workflow and safety of the workforce.

Understanding the specific needs of your business is the first step in making the right choice. Factors such as the type of inventory, frequency of access, and available space must be carefully considered to ensure an optimal layout. The variety of warehouse storage racks available—ranging from selective racks to pallet flow systems—offers tailored solutions for different operational needs.

Moreover, investing in the right warehouse storage racks can lead to long-term benefits, including improved inventory management and reduced overhead costs. As today's market demands increased efficiency, making informed decisions about storage solutions is essential for staying competitive. With the proper guidance and consideration, businesses can create a storage environment that not only meets their current needs but is also adaptable for future growth.

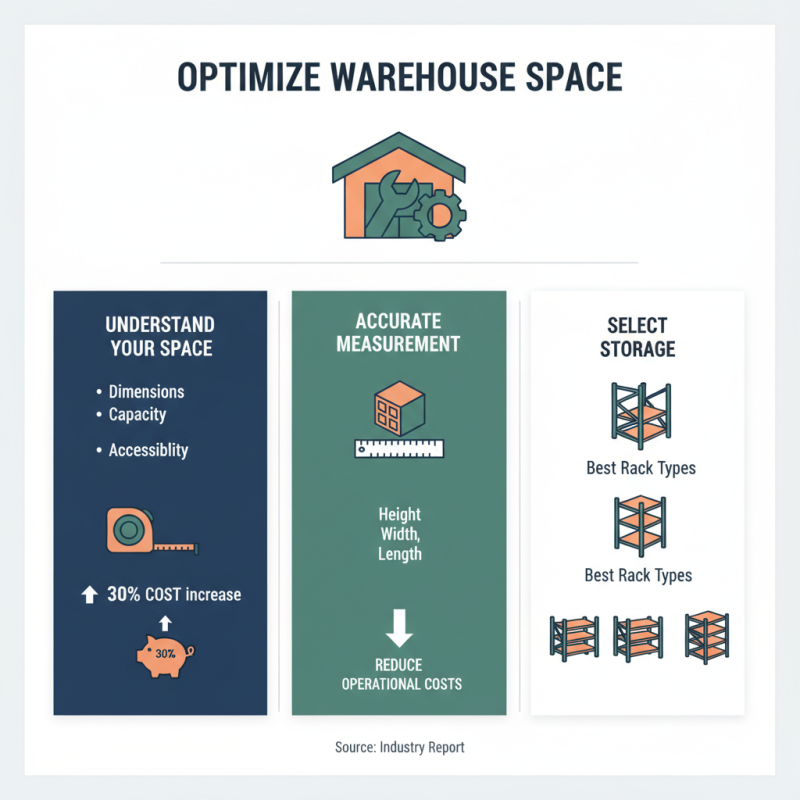

Understanding Your Warehouse Space and Layout Requirements

When planning your warehouse layout, understanding your space is essential to optimize storage and overall efficiency. A recent industry report highlights that improper space utilization can lead to a 30% increase in operational costs, making it crucial to assess dimensions, loading capacities, and accessibility. Measuring your available space accurately and considering the height, width, and length allows you to determine the best types of storage racks suited for your needs.

Tips: Consider using vertical space to maximize storage capacity by selecting high-rise racks. This not only utilizes your warehouse height but also encourages efficient retrieval practices. Additionally, leverage the aisle width by using narrow aisles if your inventory allows for it, facilitating smoother operations and quick access to products without compromising safety.

Another vital aspect is the warehouse layout’s adaptability. As businesses evolve, so do their storage requirements. According to industry analysis, flexible storage solutions can lead to a productivity increase of up to 25%. Investing in adjustable shelving or modular racks can accommodate changing inventory levels and types without necessitating a complete redesign of your warehouse. Regularly reviewing your layout ensures that you remain responsive to your business's needs, ultimately enhancing performance and productivity.

Evaluating Different Types of Warehouse Storage Racks

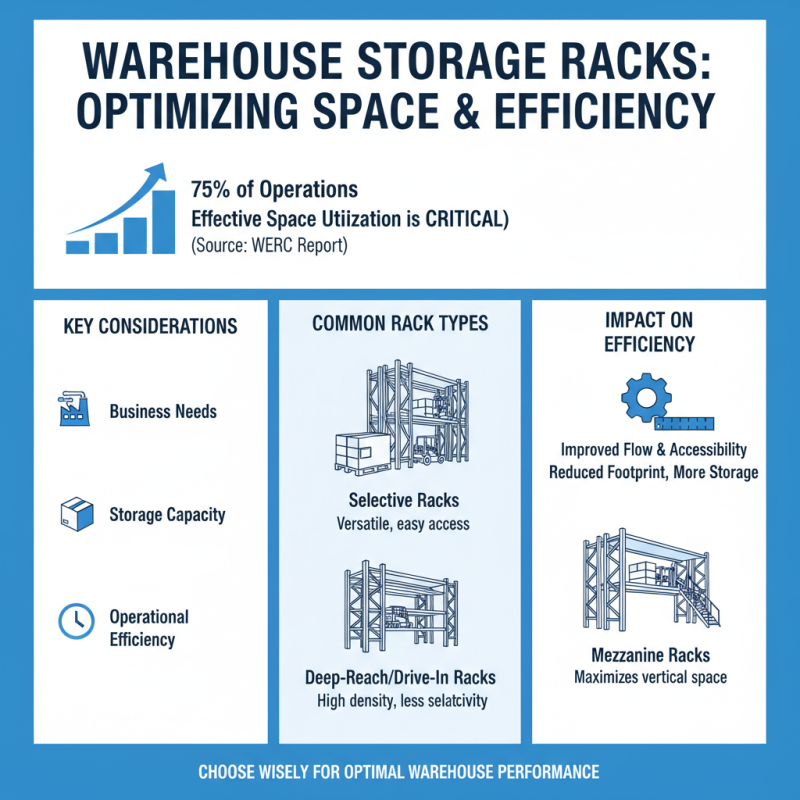

When evaluating different types of warehouse storage racks, it's essential to consider the specific needs of your business, as various rack systems can significantly impact efficiency and storage capacity. According to a recent report by the Warehousing Education and Research Council (WERC), approximately 75% of warehouse operations cite effective space utilization as a critical factor in their overall efficiency, emphasizing the importance of selecting the right storage solution.

There are several types of warehouse storage racks, including pallet racks, cantilever racks, and selective racks. Pallet racks are the most commonly used, providing outstanding storage density while allowing for quick access to inventory. WERC's 2023 statistics indicate that pallet racking systems can increase storage capacity by up to 40% compared to traditional shelving systems. On the other hand, cantilever racks are ideal for storing long or bulky items, making them suitable for industries such as lumber and manufacturing, where custom storage solutions can enhance operational speeds and reduce handling costs.

Moreover, selective racks allow for immediate access to every pallet and are designed for first-in, first-out inventory systems, which are vital for managing perishable goods. The use of selective racks can lead to a reduction in order picking times by up to 20%, further supporting the need for businesses to analyze their inventory turnover rates and choose a system that aligns with their operational workflows. By understanding these different types of warehouse storage racks, businesses can make informed decisions that will enhance productivity and support growth.

Assessing Load Capacity and Durability Needs for Racks

When choosing warehouse storage racks for your business, assessing load capacity and durability needs is essential. The load capacity indicates how much weight each rack can support without compromising structural integrity. It's critical to analyze your typical inventory weights and distribution to select racks that can handle your specific requirements. Heavy-duty racks may be necessary for storing bulky items, while lighter options could suffice for less dense products.

Tip: Before making a purchase, conduct a thorough inventory assessment to determine the maximum weight your racks will support. This can help avoid potential accidents or equipment failure.

Durability is another key factor. Racks experience wear and tear due to frequent loading and unloading, so selecting materials that can endure regular use is vital. Consider racks made from steel or galvanized materials which offer better resistance against corrosion and bending compared to lighter materials. Additionally, check for any warranties or service agreements that guarantee long-term usability.

Tip: Regular maintenance checks can prolong the life of your racks and ensure they remain in optimal condition. Inspect for any signs of damage or wear, and address issues promptly to maintain safety and functionality.

How to Choose the Right Warehouse Storage Racks for Your Business Needs

| Rack Type | Max Load Capacity (lbs) | Material | Durability Rating (Years) | Best Use |

|---|---|---|---|---|

| Selective Rack | 4000 | Steel | 10 | General Storage |

| Drive-In Rack | 5000 | Steel | 10-15 | High-Density Storage |

| Mobile Rack | 3000 | Aluminum/Steel | 8-12 | Flexible Storage |

| Cantilever Rack | 6000 | Steel | 15 | Long Goods Storage |

| Pallet Rack | 3000 | Steel | 10-15 | Bulk Storage |

Considering Accessibility and Space Optimization Techniques

When selecting warehouse storage racks, accessibility and space optimization are critical factors that can significantly influence the efficiency and productivity of a storage facility. According to a report by the Warehousing Education and Research Council (WERC), businesses can improve their space utilization by up to 30% through the effective design of storage systems. This highlights the importance of focusing on both accessibility and layout when choosing the right racks.

One effective technique for enhancing accessibility is the implementation of a selective racking system, which allows for easy retrieval of items in any order. This can be particularly beneficial in operations that require fast-paced picking and packing, as noted in the 2022 Storage and Handling Industry report. Additionally, utilizing vertical space by opting for taller racks can help in optimizing floor space, allowing warehouses to accommodate more inventory without expanding their footprint. The strategic arrangement of aisles and the use of narrow-aisle racking can further maximize accessibility and flow, ensuring that products are not only stored efficiently but are also easy to access when needed.

Moreover, the integration of technology, such as automated storage and retrieval systems (AS/RS), has been shown to enhance both accessibility and space optimization. A study from the International Warehouse Logistics Association (IWLA) noted that warehouses employing AS/RS experienced a 50% increase in storage density while also reducing the time spent on order fulfillment. By carefully considering these aspects, businesses can create a well-organized warehouse that meets their operational needs and boosts overall efficiency.

Comparison of Warehouse Storage Rack Types

This bar chart illustrates the percentage of usage for various types of warehouse storage racks. Selective racks are the most commonly used type, reflecting their versatility and accessibility. Drive-in racks and push back racks are also popular, particularly for high-density storage needs. Cantilever and pallet flow racks serve specialized purposes, contributing to their lower usage percentages.

Budgeting for Warehouse Rack Purchases and Maintenance

When budgeting for warehouse rack purchases and maintenance, it’s essential to consider both the initial investment and the ongoing costs associated with these systems. According to the 2022 Warehouse Equipment Report, approximately 30% of a warehouse's operational budget can be allocated to storage equipment, highlighting the importance of careful financial planning. Businesses should assess their specific operational needs, size, and storage capacity to determine the most appropriate type of racks, whether they are selective, drive-in, or pallet flow racks. This data-driven approach ensures that financial resources are utilized effectively while meeting the demands of inventory management.

Tips for Budgeting: Start by conducting a thorough analysis of your current and projected inventory levels to estimate the required rack capacity accurately. Next, factor in maintenance costs, which can range from 10-20% of the initial purchase price annually, depending on the type of racks and the environment in which they are used. Regular inspections and maintenance not only extend the lifespan of the racks but also prevent costly downtime.

Additionally, it's wise to explore financing options, as many suppliers offer flexible payment plans that can ease cash flow concerns. Keep in mind that investing in high-quality racks can lead to significant long-term savings by minimizing damage to inventory and maximizing space utilization, further enhancing the overall efficiency of warehouse operations.

Related Posts

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

Why Choose Pallet Racking in Brisbane for Your Warehouse Storage Needs

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More