WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Welded Wire Mesh for Your Project?

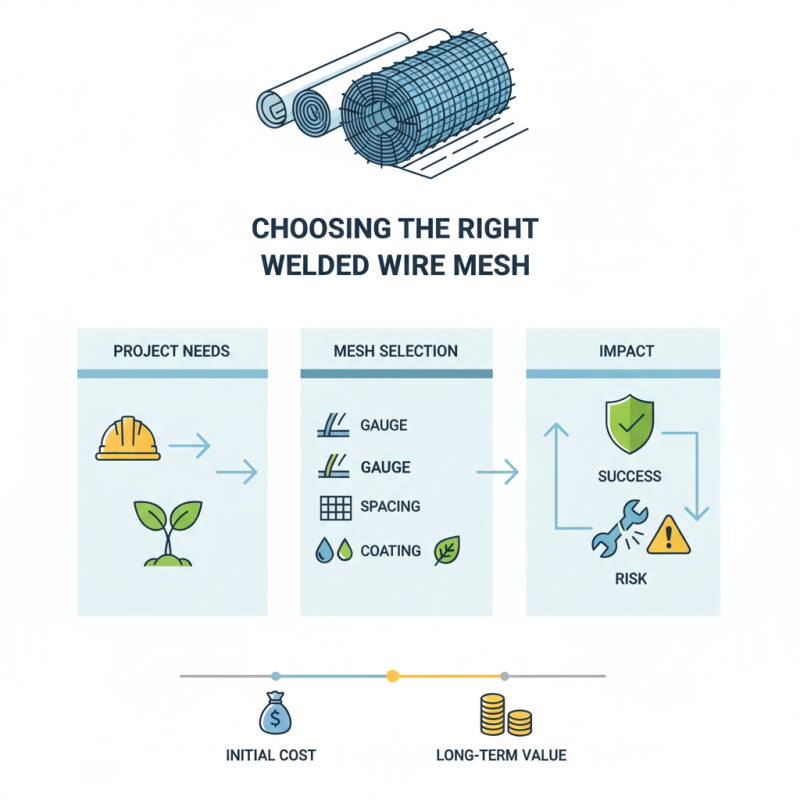

Choosing the right welded wire mesh for your project can significantly impact its success. The global welded wire mesh market was valued at approximately $6.26 billion in 2020 and is projected to grow. This growth indicates increasing demand across various industries, including construction and agriculture.

When selecting welded wire mesh, several factors must be considered. The gauge, spacing, and type of wire can affect strength and durability. Reports suggest that heavier gauge options are better for high-stress applications. Also, the right coating, such as galvanized or vinyl, can enhance corrosion resistance.

However, buyers often overlook crucial details. Many focus solely on price, ignoring the long-term benefits of quality materials. It's essential to reflect on the project's needs. Choosing subpar welded wire mesh can lead to costly repairs or safety hazards down the line. Therefore, understanding the specific requirements is vital for optimal project outcomes.

Understanding Welded Wire Mesh: Key Features and Types

Welded wire mesh is a versatile material used across various projects. It consists of intersecting wires that are welded at each junction. This structure provides strength and stability. There are different types of welded wire mesh available. Understanding these types is essential for making the right choice.

One common type is galvanized mesh. It is coated to resist rust and corrosion. This makes it suitable for outdoor applications. There are also stainless steel options. Stainless steel welds can handle high temperatures. These are ideal for industrial uses. Each type has unique properties. Depending on your project, you may need a specific type.

Some projects may not require the strongest mesh. But improperly choosing a weaker option could lead to failure. Always consider the weight and tension applied. Look closely at the gauge of wire. A thicker gauge means better strength but also more weight. Sometimes, a balance needs to be struck between cost and durability. Reflecting on these details can lead to a more informed decision.

Assessing Your Project Needs: Size, Strength, and Material

When selecting welded wire mesh for your project, assessing your specific needs is crucial. Consider size first. Typical mesh sheets are available in various dimensions. For example, a 4x8 feet sheet may be ideal for fencing, while smaller sizes can suit garden enclosures. An industry report noted that about 35% of projects fail due to incorrect sizing. Always measure your area accurately.

Strength is another essential factor. Mesh varies in wire gauge and tensile strength. A higher gauge indicates thinner wire but may not provide enough support for heavy-duty uses. Establish the load your mesh must withstand. A weaker mesh can lead to structural failure. Data shows that welded wire mesh with a tensile strength of at least 50,000 psi is suitable for construction projects.

Tip: Always look for certification proof. This indicates the mesh meets industry standards.

Material choice matters too. Common types like galvanized steel, stainless steel, or coated alternatives each serve different functions. For instance, galvanized wire is excellent for outdoor applications. However, it can rust over time. In contrast, stainless steel offers durability but at a higher cost. Consider the environment and your budget carefully.

Tip: Think ahead about potential wear and tear. A more durable mesh may save you money in the long run.

How to Choose the Right Welded Wire Mesh for Your Project?

| Project Type | Mesh Size (inches) | Wire Diameter (gauge) | Material | Strength Rating (lbs) | Ideal Use Cases |

|---|---|---|---|---|---|

| Garden Fencing | 2 x 4 | 14 | Galvanized Steel | 450 | Animal Enclosures, Garden Protection |

| Hog Pen | 4 x 4 | 12 | Stainless Steel | 800 | Livestock Enclosures, Heavy-Duty Applications |

| Construction Site | 6 x 6 | 10 | Black Steel | 1000 | Concrete Reinforcement, Temporary Barriers |

| Security Fencing | 2 x 2 | 16 | Galvanized Steel | 300 | Perimeter Security, Garden Protection |

| Decorative Applications | 1 x 1 | 18 | Vinyl Coated | 200 | Art Projects, Crafts, Garden Accents |

Factors to Consider: Corrosion Resistance and Coating Options

When selecting welded wire mesh, corrosion resistance is a key factor. Different environments affect the longevity of the mesh. For instance, coastal areas experience high humidity and salinity, which can accelerate rust. In such cases, consider materials that resist corrosion effectively. Stainless steel is often preferred, providing excellent durability against harsh elements.

Coating options are equally important. Galvanized wire mesh offers a protective zinc layer, enhancing resistance to rust. You can also find plastic-coated options, which provide an extra barrier. These are ideal for projects exposed to moisture. However, coating may wear off over time, revealing the wire beneath, which requires monitoring.

Choosing the right welded wire mesh depends on your specific needs. Evaluate whether the advantages of a particular type outweigh potential downsides, like cost or aesthetic appeal. Each project may present different challenges, demanding careful consideration and sometimes, trial and error. While some options seem perfect at first glance, real-world performance can differ. Choosing wisely can save you from future headaches.

Budgeting for Your Welded Wire Mesh Project: Cost vs. Quality

When budgeting for your welded wire mesh project, it's essential to understand the balance between cost and quality. Cheaper options may seem appealing, but they often compromise strength and durability. A low-cost mesh can lead to repairs and replacements sooner than expected, which increases overall expenses. Quality materials, despite their higher price tag, can save you money in the long run.

Tip: Consider the long-term costs. Investing in high-quality mesh can reduce maintenance needs. Evaluate the factors that contribute to mesh durability, like wire gauge and finish. Lighter gauges may bend or rust more quickly, leading to unforeseen costs down the road.

It's important to reflect on your project's specific needs. Will the mesh be exposed to harsh weather elements? If so, lower-quality options might not withstand these conditions. Seek out materials that offer protection against corrosion or additional treatments.

Tip: Prioritize based on application. If your project demands high strength, it may be worth spending more initially. Think about how the mesh will perform in the intended environment. Always weigh your immediate budget constraints against the potential for future expenses versus quality benefits.

Installation Tips: Best Practices for Using Welded Wire Mesh

When installing welded wire mesh, preparation is key. Start by measuring the area where the mesh will be placed. Use sturdy stakes or markers to outline the space. This helps ensure accurate cuts and proper fit. Pay attention to the ground surface; it should be level and clear of debris. A smooth base reduces the risk of future issues.

Next, cut the mesh carefully. Use wire cutters or a saw for clean edges. Imperfect cuts can create sharp points. These could pose safety hazards later. Always wear gloves during this process. When laying the mesh down, overlap edges where possible. This adds strength and stability. Secure the mesh with anchors or ties. Ensure that the tension is even throughout.

After installation, inspect for any loose sections. This can help avoid potential failures in the future. Proper installation may require adjustments. Don’t hesitate to rethink your steps if something seems off. Take your time, focus on each section, and double-check your work. Patience and attention to detail will lead to successful results.

Welded Wire Mesh Selection for Various Projects

Article Source:

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More