WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Cantilever Racking System?

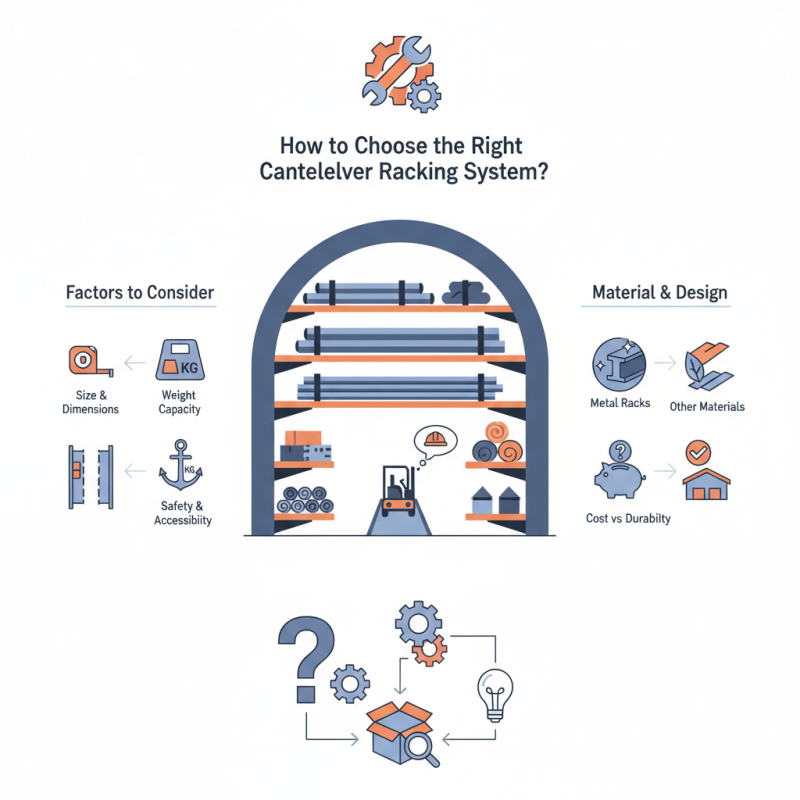

Choosing the right cantilever racking system is crucial for efficiency. Many businesses struggle with this decision. Is it the size that matters? Or the weight capacity?

A well-selected cantilever racking system can optimize storage in warehouses. Imagine a narrow aisle filled with large, bulky items. This setup prevents damage and improves accessibility. Yet, not every racking system fits all needs.

Consider different materials and designs. Metal racks are popular, but they may not be suitable for lighter items. Sometimes, a cheaper option might seem tempting. However, it could lead to unexpected costs down the line. Reflect on your specific requirements. What goods do you store? Understanding this can guide you to the perfect solution.

Understanding Cantilever Racking: Definition and Components

Cantilever racking is essential for storing long and bulky items. It consists of vertical posts and horizontal arms. Each arm supports heavy loads. According to the Materials Handling Industry (MHI), proper racking can increase storage efficiency by up to 60%. This is crucial for businesses dealing with large materials.

Understanding the components of cantilever racking is key. The vertical posts offer stability. Arms can be adjustable to accommodate different sizes of items. In fact, reports show that adjustable racks can improve space utilization by 30%. This flexibility allows businesses to adapt as inventory changes, which is vital for growth.

Custom designs might seem appealing, but they can also lead to inefficiencies. A well-designed system balances functionality and cost. Research indicates that 20% of racking systems fail to optimize space. This failure often stems from poor planning or unsuitable components. Regular assessments of your racking system can prevent these issues. Keeping an eye on your storage strategy is essential for long-term success.

Analyzing Load Capacity Requirements for Cantilever Racking Systems

When choosing a cantilever racking system, assessing load capacity is crucial. You need to know the weight of items. Consider the types of materials you'll store. Each item has a different weight, which influences your choice.

Evaluate how these items will be arranged. If your load varies greatly, it may require a flexible solution. Sometimes users overlook specific weight factors. This lack of detail can lead to mistakes. You'll want to prevent overloading racks, as this can cause damage.

Moreover, be mindful of spacing. Items might be stacked high or wide. Ensure your racking can accommodate this without compromising safety. Inspect the integrity of the columns and arms regularly. Don’t ignore worn-out sections; they need attention. Regular evaluations help maintain optimal functionality.

How to Choose the Right Cantilever Racking System? - Analyzing Load Capacity Requirements for Cantilever Racking Systems

| Racking Type | Max Load Capacity (lbs) | Arm Length (inches) | Height (inches) | Number of Levels |

|---|---|---|---|---|

| Single-Sided Cantilever | 1,500 | 48 | 96 | 3 |

| Double-Sided Cantilever | 2,000 | 60 | 120 | 4 |

| Heavy-Duty Cantilever | 3,500 | 72 | 144 | 5 |

| Light-Duty Cantilever | 800 | 36 | 72 | 2 |

| Medium-Duty Cantilever | 1,200 | 48 | 96 | 3 |

Evaluating the Space and Configuration Needs for Effective Storage

Choosing the right cantilever racking system hinges greatly on understanding your space and configuration needs. A recent industry report shows that maximizing vertical space can increase storage efficiency by up to 40%. When evaluating your warehouse layout, consider aisle width, load types, and the height of your ceilings. Each factor can significantly influence the racking system you choose.

Analyzing your inventory can also guide your decision. For example, bulkier items like lumber or steel tubes require wider arms and a robust structure. In contrast, lighter materials may need a different approach. Research indicates that mismatched racking systems can lead to space waste. Configure your racking to avoid dead zones. A warehouse layout that does not accommodate your specific needs may result in ineffective use of space.

Regularly assess your racking system to ensure it meets evolving storage demands. An unsuitable setup may lead to frequent reorganizations. This not only wastes time but can also compromise safety. One survey revealed that 30% of facilities encounter safety issues due to improper racking. Prioritize regular evaluations. Adjustments based on real-time data can keep your storage system efficient and safe.

Choose the Right Cantilever Racking System

This bar chart compares the maximum load capacity for different types of cantilever racking systems, helping you choose the right one based on your storage needs.

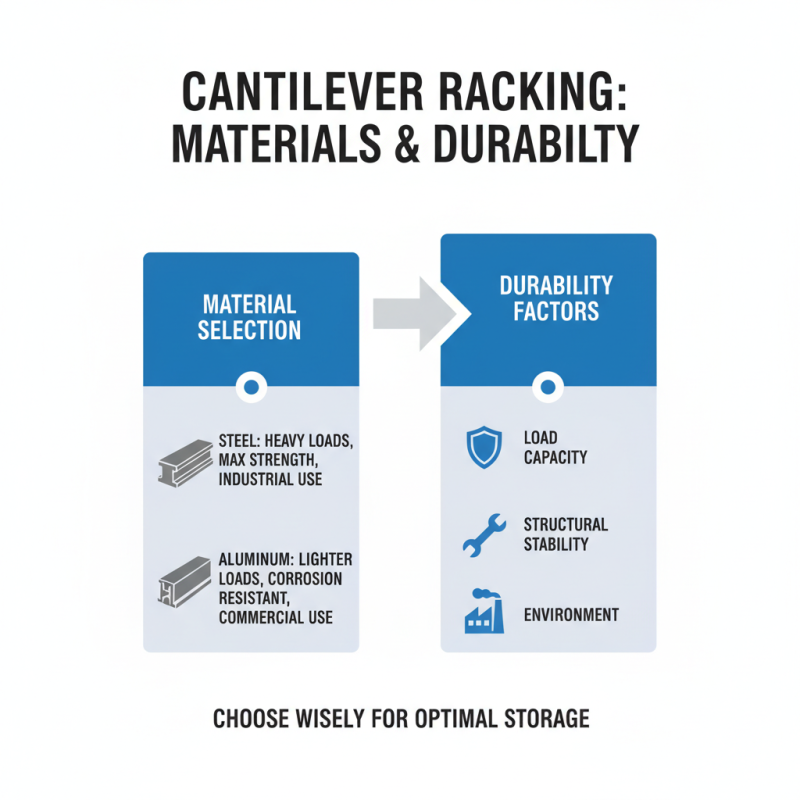

Selecting Materials and Durability Factors for Cantilever Racks

Choosing the right cantilever racking system involves careful consideration of materials and durability. When selecting materials, opt for steel or heavy-duty aluminum. These materials provide strength and stability. Think about your specific storage needs. If you're storing lightweight items, aluminum might suffice. For heavier loads, steel is ideal.

Tips: Always check load ratings. Overloading racks can lead to failures. Inspect the finish as well. A powder-coated finish can resist corrosion, making racks last longer.

Durability is another key factor. Look for racks designed to withstand heavy usage. Ask about warranties. A longer warranty often indicates higher quality. Don't overlook environmental factors. Racks exposed to moisture need extra protection. Corrosion can compromise structural integrity over time.

Tips: Consider the warranty length on your racks. It reflects the manufacturer's confidence. Regular maintenance is essential for longevity. Clean and inspect racks periodically to ensure safety.

Considering Safety Regulations and Compliance Standards in Racking Systems

When selecting a cantilever racking system, safety regulations must be prioritized. Compliance with OSHA standards is essential to avoid workplace accidents. According to the American National Standards Institute (ANSI), improper racking setups can lead to serious injuries. Data shows that up to 50% of racking-related incidents stem from non-compliance with safety guidelines.

Each cantilever system should be evaluated for its load capacity. The National Bureau of Labor Statistics reports that around 20,000 injuries occur annually due to racking collapses. Implementing a racking system that meets or exceeds regulatory standards is vital. Inattention to weight limits and proper installation can result in unwelcome challenges. Providing training to staff on safety measures can also enhance compliance.

Periodic inspections are crucial for maintaining compliance. Research indicates that racking systems require evaluations at least twice a year. Inspections help identify wear and tear or misalignment. Potential hazards can arise when these practices are overlooked. Tracking adjustments and repairs ensures that the racking systems remain compliant. Remember, neglecting safety can endanger lives and disrupt operations.

Related Posts

-

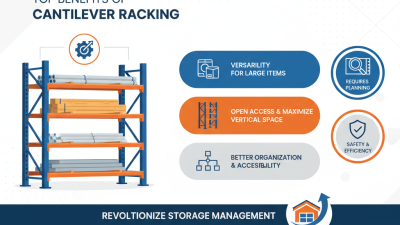

Top Benefits of Cantilever Racking for Warehouse Storage Solutions?

-

Top 2025 Pallet Racking Solutions in Melbourne for Your Warehouse Needs

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

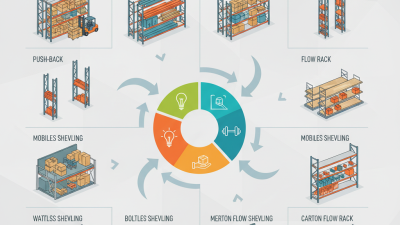

Top 10 Racking and Shelving Systems for Efficient Storage Solutions?

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

What is Pallet Shelving and How Can It Optimize Your Storage Solutions

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More