WSS Blog

Follow our latest updates and thoughts on our industry2026 How to Choose the Right Uline Pallet Racks for Your Warehouse?

When it comes to selecting the right Uline pallet racks for your warehouse, the choices can be overwhelming. A well-organized storage solution is essential for efficiency and safety. Uline pallet racks offer various designs and configurations. These racks accommodate different types of products and maximize vertical space.

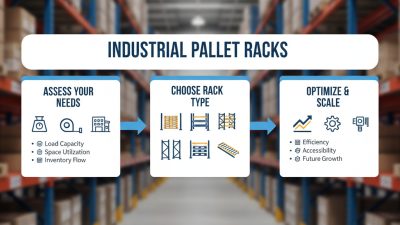

Choosing the correct rack is not just about size. It's also about material, weight capacity, and accessibility. Reflecting on your specific needs is crucial. Consider your inventory turnover and space layout. Poorly chosen racks can lead to inefficiencies and safety hazards. Uline pallet racks should enhance functionality, not complicate workflow.

Take the time to evaluate your warehouse requirements. Assess the types of products you store. Understand how often you will access them. This process may require adjustments and might feel tedious. However, investing time in selecting the right Uline pallet racks pays off in the long run. A well-planned setup can transform your storage and increase productivity.

Factors to Consider When Selecting Uline Pallet Racks

Choosing the right pallet racks for your warehouse is vital. Several factors come into play. Load capacity is primary. Assess the weight of your items. Some racks hold 3,000 pounds or more per shelf. Ensure your selected racks can handle this without compromising safety.

Warehouse layout matters too. Aisle width should allow for easy access. Aisles that are too narrow can hinder operations. Studies show that optimizing space can increase storage capacity by up to 30%. Think about future needs. Will you expand? If so, choose racks that can adapt.

Durability is another key factor. Metal racks generally offer better longevity than wood. Look for stored data on maintenance costs. It's reported that durable racks can save companies approximately 15% on long-term expenses. Also consider the installation process. Complicated setups can lead to errors. Choose user-friendly designs to avoid headaches.

Factors to Consider When Selecting Pallet Racks for Your Warehouse

Types of Uline Pallet Racks and Their Applications

When selecting pallet racks for your warehouse, understanding different types is crucial. Each type serves unique functions, making the choice process important. Drive-in racks, for example, maximize storage density. They allow easy access for forklifts, perfect for high-density storage. However, they require proper organization to prevent damage.

Another popular type is selective racks. These racks provide individual access to each pallet. They are versatile and easy to use but can lead to wasted space if not planned carefully. Consider your stock rotation needs. Make sure to choose a type that fits your inventory turnover.

Tips: Use a diagram of your warehouse layout. Visual tools help in choosing the right rack type. Always think about safety and accessibility. Regularly review your storage needs; they may change. It's crucial to ensure the rack system aligns with your warehouse goals.

Evaluating Your Warehouse Space for Pallet Rack Configuration

When evaluating your warehouse space for pallet rack configuration, the dimensions of your area are crucial. Measure the length, width, and height accurately. This allows you to visualize the layout better. Consider obstacles like doors and machinery. These can limit usable space and impact how you position the racks.

Next, think about your inventory needs. Different types of products require specific storage configurations. If you have taller items, higher racks may work best. Conversely, shorter items can be stored in lower racks for easy access. Remember to account for aisle space too. Too narrow aisles can slow down operations.

You might find that not all space can be utilized efficiently. It's important to reflect on your current setup. Notice what areas cause congestion. These insights can help optimize future arrangements. Employing a thoughtful approach to your warehouse layout will enhance efficiency. Be prepared to adjust as your inventory changes.

Understanding Safety Standards and Regulations for Pallet Racks

When selecting pallet racks for a warehouse, safety standards are crucial. You want to ensure that your equipment can withstand daily operations. Various regulations exist, guiding the design and load capacity of these racks. Compliance with these standards protects employees and products alike.

Consider the load capacity rating. Each pallet rack has a specified weight limit. Exceeding this limit can lead to structural failures. Regular inspections are key to maintaining safety. Look for signs of wear or damage on the racks. This proactive approach can prevent accidents before they happen.

Understanding your warehouse layout also matters. Racks should allow for easy access and maximize space. It’s essential to think about aisle widths and reach. Poorly designed layouts can lead to congestion and difficulty in retrieval. Reflecting on past mistakes helps refine your approach to future rack installations. Aim for both efficiency and safety in your choices.

2026 How to Choose the Right Uline Pallet Racks for Your Warehouse? - Understanding Safety Standards and Regulations for Pallet Racks

| Pallet Rack Type | Weight Capacity (lbs) | Height (ft) | Depth (in) | Material | Safety Standards Compliance |

|---|---|---|---|---|---|

| Selective Racking | 3,000 | 10 | 36 | Steel | ANSI MH16.1 |

| Drive-In Racking | 4,500 | 12 | 42 | Aluminum | OSHA Compliant |

| Cantilever Racking | 5,000 | 14 | 48 | Steel | SFI Certified |

| Shelf Racking | 2,200 | 8 | 30 | Metal | ISO 9001 |

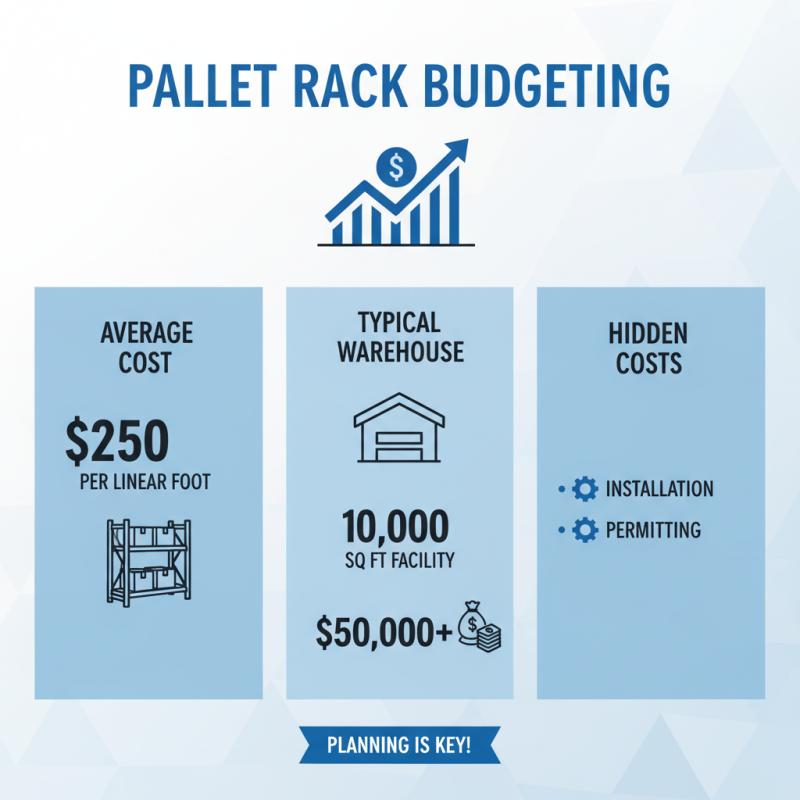

Cost Analysis: Budgeting for Uline Pallet Racks in Your Warehouse

When budgeting for pallet racks, costs can vary significantly. A recent industry report indicates that the average cost of a pallet rack system is around $250 per linear foot. Depending on your warehouse size, this can add up quickly. For a 10,000 square foot facility, you could be looking at costs exceeding $50,000. Be mindful of hidden costs, such as installation and permitting.

Consider your specific needs. Selective racks typically offer lower initial costs. However, drive-in racks may improve storage density. A thorough analysis of your inventory flow is essential. Some business owners overlook this step, leading to poor decisions. Ignoring the logistics of your warehouse can result in inefficient use of space and resources.

Maintenance costs are another aspect to examine. Routine inspections and repairs are necessary to keep your racks safe. According to industry standards, regular maintenance can prevent hazards. Skipping this step may save money initially, but could lead to greater expenses in the long run. Balancing upfront costs with long-term investment is crucial to making the right choice for your warehouse.

Related Posts

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

Top 10 Racking and Shelving Systems for Efficient Storage Solutions?

-

What are the Best Commercial Racking Systems for 2026?

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More