WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Pallet Rack Beams for Your Warehouse Storage Needs

When it comes to optimizing warehouse storage, selecting the right pallet rack beams is a crucial decision that impacts both efficiency and safety. Pallet rack beams serve as the backbone of your racking system, supporting the weight of stored goods while allowing for easy access and organization. The right choice not only aids in maximizing storage capacity but also minimizes the risk of accidents and inventory damage.

In this guide, we will explore the essential factors to consider when choosing pallet rack beams, ensuring that you meet your storage needs while adhering to industry standards. From the materials and weight capacity to the compatibility with your existing shelving systems, understanding these elements will help streamline your selection process. Whether you are outfitting a new warehouse or upgrading an existing one, making informed decisions about pallet rack beams is vital in creating an efficient and safe working environment.

Understanding Pallet Rack Beams and Their Functions

Pallet rack beams are essential components of a warehouse storage system, designed to support and organize palletized goods efficiently. Understanding their functions can significantly enhance the effectiveness of your storage operations. These beams serve as horizontal supports that connect vertical frame uprights, creating a robust structure that holds varying weights and sizes of inventory. The choice of material, such as steel, and the specific design of the beams can affect the overall load capacity and durability, making it crucial to select the right type for your specific needs.

In addition to providing stability, pallet rack beams also dictate the accessibility and organization of stored items. By choosing the appropriate beam lengths and heights, you can optimize your warehouse layout, ensuring that items are easily reachable while maximizing vertical space. Adjustable beam settings add flexibility, allowing for quick reconfiguration as your inventory needs evolve. Furthermore, additional features like safety clips and beam capacities help ensure that your storage solution not only meets functional requirements but also adheres to safety standards, minimizing the risk of accidents in the warehouse environment.

How to Choose the Right Pallet Rack Beams for Your Warehouse Storage Needs

| Beam Type | Load Capacity (lbs) | Length (inches) | Beam Material | Use Case |

|---|---|---|---|---|

| Standard Beam | 2,500 | 96 | Steel | General Storage |

| Heavy Duty Beam | 3,500 | 108 | Steel | Bulk Storage |

| Teardrop Beam | 2,800 | 96 | Steel | Flexible Storage |

| Cantilever Beam | 4,000 | 120 | Steel | Long Materials Storage |

| Pallet Support Beam | 2,200 | 72 | Steel | Support for Pallets |

Assessing Your Warehouse Space and Storage Requirements

When selecting pallet rack beams, a comprehensive understanding of your warehouse space and specific storage needs is crucial. Begin by assessing the dimensions of your warehouse, including height, width, and length. This analysis will help determine how many levels of racks can fit within your space and how to maximize vertical storage. Don't forget to consider the layout of your facility, including aisles, doors, and other structural elements that will impact accessibility and flow.

Tip: Use a warehouse layout tool or software to visualize different configurations of your pallet racks. This can help you identify the most efficient use of space while ensuring operability and safety.

Next, take stock of the types of products you plan to store. Consider the weight, size, and storage conditions needed for your inventory. Different goods require different beam specifications; for instance, heavy items might need more robust, deeper beams. Understanding the specifics of your load will guide your selection and ensure that your setup meets both the safety standards and operational efficiency required for your warehouse.

Tip: Regularly review your inventory turnover to adjust rack designs and beam choices based on changing storage requirements over time. This proactive approach will help you maintain an organized and efficient warehouse.

Different Types of Pallet Rack Beams Explained

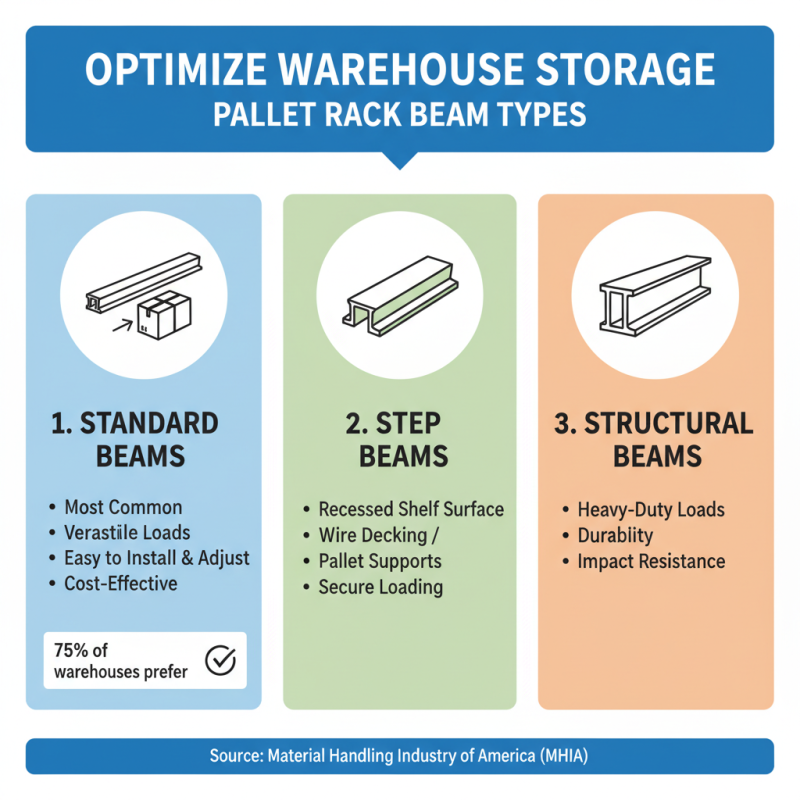

When selecting pallet rack beams for warehouse storage, understanding the different types available is crucial for optimizing space and efficiency. Pallet rack beams generally fall into three categories: standard beams, step beams, and structural beams. Standard beams are the most common type, providing a versatile option that can handle various loads. They typically feature a simple design, making them easy to install and adjust, which is essential for warehouses that require frequent reconfiguration. According to a report by the Material Handling Industry of America (MHIA), 75% of warehouse operators prefer using standard beams due to their adaptability and cost-effectiveness.

Step beams, on the other hand, offer unique advantages, especially for storing multiple pallets or materials. These beams are designed with a step that allows for the secure placement of pallets, reducing the risk of load slippage. This design is particularly beneficial in high-density storage environments where maximizing vertical space is key. Research from the Warehouse Efficiency Association suggests that step beams can increase storage capacity by up to 20% when compared to conventional beams, making them a valuable consideration for warehouses focused on maximizing their overall footprint.

Structural beams are designed for heavy-duty applications, ideal for facilities dealing with significantly larger and heavier loads. These beams are often made from thicker materials and have a higher load capacity, ensuring stability and safety in environments with rigorous operational demands. The Warehousing and Logistics Report highlights that utilizing structural beams can decrease the likelihood of rack failure by 30%, thus significantly enhancing workplace safety. By considering the specific needs of your warehouse and the types of goods being stored, you can make an informed decision on the most suitable pallet rack beams for your operations.

Factors to Consider When Selecting Pallet Rack Beams

When selecting pallet rack beams for warehouse storage, several factors are crucial to ensure efficiency and safety in your operations. One of the primary considerations is the load capacity of the beams. Industry standards, as outlined in a recent report by the Rack Manufacturers Institute, indicate that beams should be selected based on the maximum weight they will support, as well as the distribution of that weight across the rack system. A common recommendation is to utilize beams that can handle at least 30% more than the expected load to accommodate for dynamic forces, ensuring structural integrity and longevity.

Another important factor is the height and configuration of your warehouse. According to the Material Handling Industry of America, optimizing vertical space is critical. Therefore, it's essential to choose beams that can fit your existing racking dimensions while allowing for efficient picking and inventory management. Additionally, consider the type of pallets you will be using. Different beam designs can accommodate various pallet sizes and weights, so understanding your inventory's specifications will help you select the most appropriate beam style. Moreover, factors such as accessibility, aisle widths, and forklift operation must also be assessed to maximize space utilization and streamline your workflow.

Best Practices for Installing and Maintaining Pallet Rack Beams

When installing pallet rack beams, it's crucial to ensure proper alignment and stability. Start by inspecting the floor for any unevenness that could affect the rack’s integrity. Use a level to confirm that the beams are not only even but also securely attached to the uprights. Proper installation reduces the risk of accidents and enhances storage efficiency.

**Tips**: Always use the correct tools recommended for assembling pallet racks. Double-check connections and fastenings before loading the beams to ensure they can support the intended weight. This practice minimizes the chances of structural failures.

Regular maintenance of pallet rack beams is essential for safety and longevity. Schedule routine inspections to check for signs of wear, such as bent or corroded components. Ensure that the racks are not overloaded and that items are stored correctly to maintain balance. Keeping your pallet racks in good condition will help avoid costly repairs and potential safety hazards.

**Tips**: Implement a weekly maintenance checklist for warehouse staff to make sure all safety and structural aspects of the pallet racking are monitored. Address any issues immediately to ensure a safe working environment.

Warehouse Storage Needs: Pallet Rack Beam Selection

Related Posts

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More