WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Industrial Racking System For Your Needs?

Choosing the right industrial racking system is crucial for any warehouse or storage facility. With so many options available, it can feel overwhelming. Each type of racking system serves a specific purpose and caters to different needs. Understanding your requirements is essential.

Consider the size and weight of the items you store. This impacts the type of industrial racking you choose. Evaluate the available space. Is it wide open or filled with obstacles? Your choice will affect workflow efficiency. A well-planned racking system can save time and reduce accidents.

Many businesses overlook the importance of flexibility in their racking systems. Modular designs can adapt to changing inventory. This adaptability can be a game changer as your business grows. Yet, it is often neglected. Proper research and planning can help avoid costly mistakes. Reflect on your current setup and think about future needs.

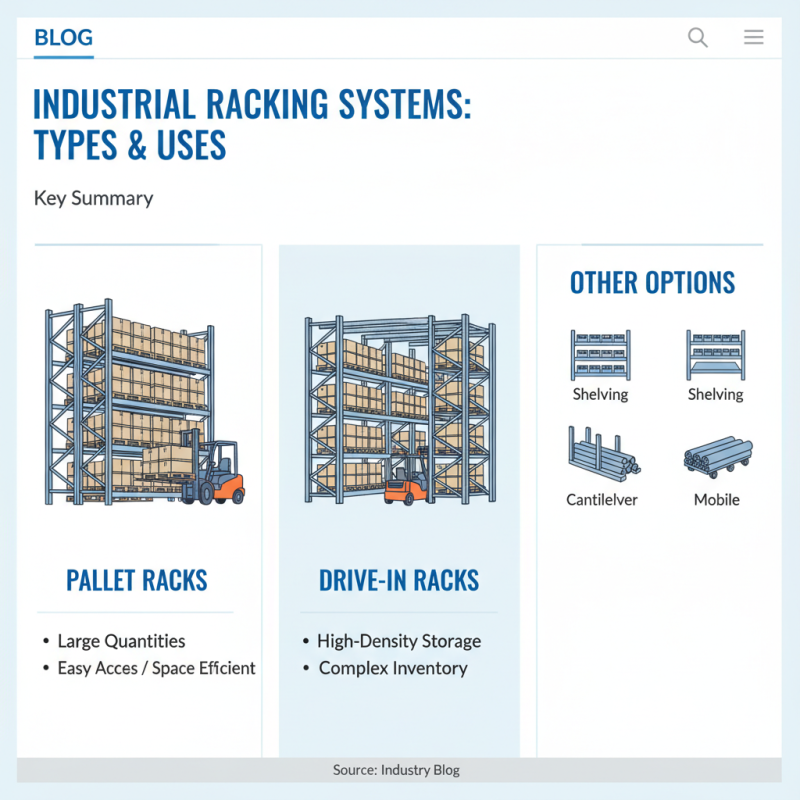

Understanding Different Types of Industrial Racking Systems

When selecting an industrial racking system, understanding the different types is essential. There are several options available, each serving unique functions. For example, pallet racks are popular for storing large quantities of goods. They allow easy access and efficient space utilization. Drive-in racks are better for high-density storage but can complicate inventory management.

Consider your storage needs. Assess the weight and size of your products. Some racking systems accommodate heavier loads. Others may be suitable for lighter items. Choose a system that matches your operational flow. Understand the aisle width, as it impacts your equipment and movement.

Tips for making a decision:

1. Evaluate future growth. Select a versatile racking system that can expand as you grow.

2. Consider safety features. Choose systems that meet safety regulations and reduce risks.

3. Test the system if possible. Real-world use can reveal hidden challenges or benefits.

Remember, no racking system is perfect. Regularly evaluate its effectiveness. Watch for signs of wear or inefficiency. An imperfect system may require adjustments over time. Your choices should adapt as your needs change.

Assessing Your Storage Space Requirements for Racking

When assessing your storage space requirements for racking, start by measuring your area. Know the height, width, and depth. This simple step can save you from future headaches. Consider any obstacles like columns or beams. They can affect layout plans.

Next, think about what you’ll store. Different items require different racking. Heavy pallets need sturdy racks, while smaller items may fit in shelving units. Consider the weight capacity of your racking system. It’s crucial to match capacity with actual weights to avoid accidents.

Don’t forget about accessibility. How will you reach the items stored? Plan aisles and pathways accordingly. Overcrowding spaces can lead to inefficiencies. Remember, you can always adjust if needs change. Flexibility is key. Yet, it’s tough to tweak systems after installation. Spend time upfront to ensure you get it right.

Evaluating Load Capacity and Safety Standards for Racking

When selecting an industrial racking system, load capacity is crucial. Each rack has a specific weight limit. Exceeding this limit can lead to accidents. It might seem simple, but calculating total weight is complex. Consider the weight of the items. Factor in packaging and potential inventory fluctuations. Mishaps can result in costly damages.

Safety standards are another critical aspect. Different materials and designs meet various safety criteria. Make sure your racks adhere to local regulations. Inspecting for compliance may seem tedious, but it’s vital. Inadequate safety measures put workers at risk. Racks should not sag or tilt. Frequent checks can prevent potential hazards.

Sometimes, you may overlook certain details. It’s easy to assume a system performs without issues. Regular training for staff helps to maintain safety protocols. Encourage team members to report concerns. This open communication fosters a safer workspace. Remember, racking systems serve more than just storage functions; they protect lives.

Considering Accessibility and Inventory Management Needs

When selecting an industrial racking system, accessibility is crucial. Think about how your workers will interact with the shelves. If they must stretch or climb often, injuries may occur. Consider designs that allow easy access to all items. Wider aisles can facilitate movement, but can they fit your space?

Inventory management also plays a vital role. How often do you rotate stock? If items frequently change, choose a system that adapts easily. Open shelving can be helpful for quick audits. However, more closed options might offer better organization. Assess your workflow and customize accordingly.

Review your current setup. Are there areas where efficiency dips? Engage your team for insights. Often, they can pinpoint accessibility issues. This input can guide your choice significantly. Balancing practicality and organization is essential for effective inventory management.

How to Choose the Right Industrial Racking System For Your Needs? - Considering Accessibility and Inventory Management Needs

| Racking System Type | Accessibility | Load Capacity (lbs) | Inventory Management Suitability | Optimal Use Case |

|---|---|---|---|---|

| Selective Racking | High | 3,000 | Ideal for FIFO, diverse inventory | Warehouse storage, retail |

| Drive-In Racking | Moderate | 4,000 | Best for bulk storage, limited SKUs | Food distribution, beverage storage |

| Push Back Racking | Moderate | 2,500 | Good for vapid inventory, high-density storage | Production areas, warehouses |

| Mobile Racking | Very High | 1,500 | Excellent for maximizing space | Cold storage, archival facilities |

| Cantilever Racking | High | 5,000 | Suitable for long, bulky goods | Lumber yards, manufacturing |

Analyzing Cost and Long-Term Value of Racking Systems

Choosing the right industrial racking system involves understanding both cost and long-term value. A high initial price can often deter buyers, but consider the durability of the materials. Cheaper systems may need replacements sooner. Assess how much weight your racking needs to hold. This can influence material choice and cost significantly.

Tips: Prioritize longevity. Look at materials that endure harsh environments. Steel may cost more initially but often lasts longer than lesser options. Evaluate your storage space carefully. The design can impact efficiency and cost over time. A poorly planned layout wastes space.

Don't ignore hidden costs. Installation expenses can add up. Maintenance also requires funds. Select a racking system that may seem over budget but saves money in the long run. Remember, every business grows eventually. Choose a system adaptable to future needs. Consider scalability when making your decision.

Cost Comparison of Different Industrial Racking Systems

Related Posts

-

Top 10 Racking and Shelving Systems for Efficient Storage Solutions?

-

2025 How to Optimize Your Warehouse with Commercial Racking Solutions

-

10 Best Warehouse Shelving Solutions for Optimal Space Utilization?

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

How to Choose the Right Warehouse Storage Racks for Your Business Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More