WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Industrial Pallet Racks for Your Warehouse Needs?

Choosing the right industrial pallet racks is crucial for optimizing warehouse efficiency. A well-designed racking system can increase storage capacity by 30% to 50%, according to industry reports. These racks are essential for managing inventory effectively. They also help streamline operations and reduce retrieval times.

In fact, a recent study by the Warehousing Association highlighted that nearly 60% of warehouse managers regret not investing in better pallet racking solutions. The wrong choice can lead to safety hazards and operational delays. For example, unstable racks can cause product damage and employee injuries.

It's vital to assess your specific needs carefully. Consider factors like weight capacity, accessibility, and space utilization. Not every rack suits every warehouse. The wrong fit can hinder productivity. Analyzing these details upfront can save time and resources in the long run.

Understanding Warehouse Storage Requirements for Pallet Racks

When selecting industrial pallet racks, understanding your warehouse storage requirements is crucial. Take a close look at your available space. Measure ceiling height, floor dimensions, and aisle widths. Each detail matters greatly in how you utilize your warehouse efficiently. Are there any obstacles? Myriad factors can limit your storage options.

Think about the types of products you'll store. Heavy items require sturdier racks, while lighter goods can be stored on standard shelving. Evaluating product turnover is similarly important. High-turnover items should be more accessible. In contrast, less frequently used goods can be positioned higher. Create a plan that maximizes both access and safety.

Be mindful of future needs. Consider how your inventory might change over time. Racks can be pricey, but the right choice offers flexibility. Sometimes, businesses underestimate the room needed for growth. It's vital to leave space for potential expansion. Ignoring this could lead to inefficiencies and headaches down the line. Reflect on your current choices and always ask yourself if they're truly optimal for your evolving needs.

Types of Industrial Pallet Racks and Their Applications

When selecting industrial pallet racks, understanding their types is crucial. Each type serves specific storage needs. Selective pallet racks are common. They allow for easy access to individual pallets. This type works well for warehouses with diverse inventory. However, they can take up significant floor space.

Drive-in and drive-through racks are efficient for high-density storage. Forklifts drive into the rack structure, maximizing space. Yet, retrieving specific pallets can be challenging. This may cause delays, especially if items aren’t organized.

Cantilever racks are ideal for long or bulky items. They provide clear access without vertical obstructions. However, they can become overcrowded quickly if not managed properly. Proper inventory management is necessary to ensure accessibility and safety. Understanding these applications helps in making informed decisions for warehouse efficiency.

Types of Industrial Pallet Racks and Their Applications

Key Factors to Consider When Selecting Pallet Racks

Choosing the right industrial pallet racks for your warehouse is crucial for efficiency. Start by assessing your storage needs. Consider the size and weight of the items you'll store. Heavy loads require sturdier racks. Lighter items can use simpler designs. Measure your warehouse space carefully. This prevents buying racks that are too tall or wide.

Think about the accessibility of your stored goods. Select racks that allow easy loading and unloading. Narrow aisles can save space but may slow down movement. Calculate the traffic flow of warehouse vehicles. Ensure there is enough room for them to operate safely. Review the weight capacity of each rack type. Overloading can lead to accidents and damage.

Also, reflect on the future. Will your storage needs change? Flexibility in rack designs might be beneficial. Some systems allow for expansion or reconfiguration. Regularly inspect your pallet racks, too. Maintenance can prevent issues down the line. Racks need to be durable yet adaptable. Finding this balance is key.

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs?

| Factor | Description | Recommended Options |

|---|---|---|

| Load Capacity | The maximum weight each rack can hold. | Single-deep racks, double-deep racks |

| Space Efficiency | How well racks utilize available warehouse space. | Narrow aisle racks, selective racks |

| Accessibility | Ease of accessing goods stored on racks. | Drive-in racks, push-back racks |

| Material | Type of materials used to manufacture the racks. | Steel, heavy-duty plastic |

| Adjustability | Ability to modify shelf heights as needed. | Boltless design racks, adjustable beam racks |

| Safety Features | Safety elements to prevent accidents or injuries. | Mesh backrest, safety rails |

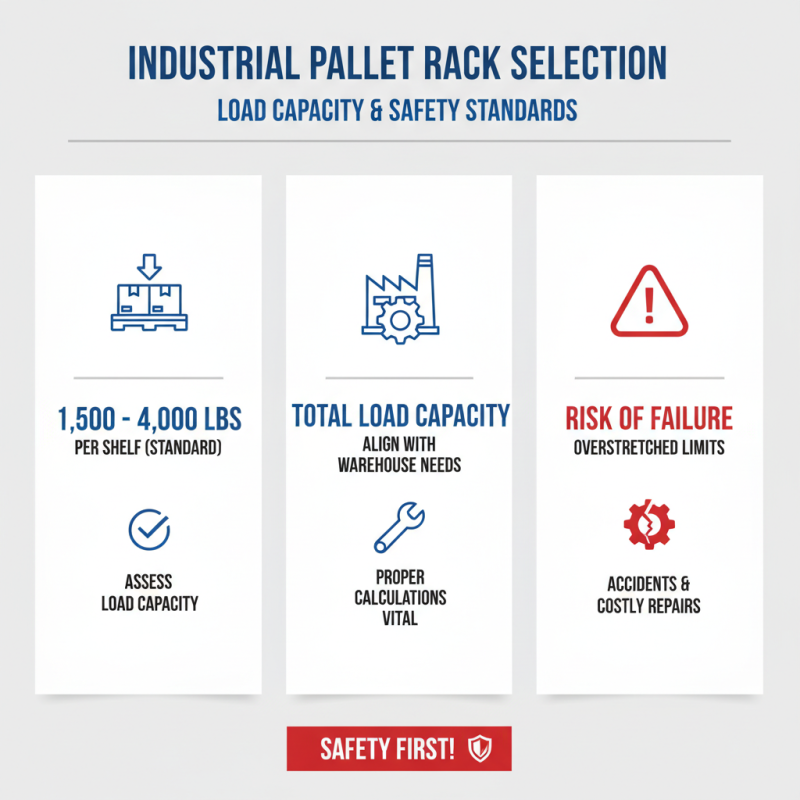

Assessing Load Capacity and Safety Standards for Pallet Racks

When selecting industrial pallet racks, assessing load capacity and safety standards is crucial. The total load capacity must align with the warehouse's specific requirements. For instance, standard pallet racks usually support a range from 1,500 to 4,000 pounds per shelf. Proper calculations are vital. If the load exceeds these limits, the structure may fail, causing accidents. Often, overstretched capacities lead to injuries and costly repairs.

Safety standards must not be overlooked. Regulations such as ANSI/RAI and OSHA guidelines dictate the safety features of pallet racks. These guidelines include bracing, aisle width, and weight distribution. Ignoring these can result in instability. According to industry data, around 60% of workplace accidents are linked to improper equipment use. This statistic emphasizes the need for adherence to safety protocols when using pallet racks.

Visual inspections play an essential role in safety management. Regular checks for wear and tear can prevent potential failures. Maintaining proper storage practices is necessary too. Overloading shelves can lead to catastrophic outcomes. Furthermore, employee training on load limits is often inconsistent. This gap in knowledge can cause significant risks. A thorough understanding of load capacities will improve safety and efficiency in any warehouse.

Space Optimization Techniques for Effective Pallet Rack Layouts

To optimize space in your warehouse, start by analyzing your inventory. Consider dimensions and weight. What items are frequently shipped? What needs more floor space? These details shape your pallet rack layout. Think about the workflow too. Is the layout easy for staff to navigate? An effective design minimizes wasted movement.

Vertical space is vital. High pallet racks can utilize overhead space. Measure the height of your warehouse. Ensure safety measures are in place. Are your racks installed securely? Evaluate aisle widths. Too narrow? It limits access. Too wide? You waste valuable space. Adjusting these widths can greatly enhance efficiency.

Consider your layout periodically. Observe if it still meets your needs. Rotate stock regularly. This habit can reveal inefficiencies. Don’t hesitate to experiment. Sometimes trial and error leads to the best solutions. Reflect on your choices. Is the existing space truly optimized, or does it feel cluttered? Continuous improvement is key.

Related Posts

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

-

How to Choose the Right Pallet Rack Beams for Your Warehouse Storage Needs

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

Top 2025 Pallet Racking Solutions in Melbourne for Your Warehouse Needs

-

How to Choose the Right Warehouse Storage Racks for Your Business Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More