WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

Choosing the right industrial pallet racks is a critical decision for any warehouse operation. With the growing demand for efficient storage solutions, understanding the various options available can significantly impact inventory management, space utilization, and overall productivity. Industrial pallet racks are designed to optimize warehouse space and enhance accessibility to products, making them an essential component of logistics and supply chain management.

When selecting industrial pallet racks, factors such as load capacity, configuration, and material need to be carefully considered. By assessing your specific warehouse needs, you can tailor a pallet rack system that not only meets current demands but also allows for future scalability. This guide will explore the key considerations and types of industrial pallet racks to help you make an informed decision that aligns with your operational goals and enhances the efficiency of your warehouse.

Understanding the Different Types of Industrial Pallet Racks

When it comes to optimizing warehouse storage solutions, understanding the different types of industrial pallet racks is crucial. The main categories of pallet racks include selective, drive-in, cantilever, and push-back racks, each serving specific logistical needs. Selective pallet racks, the most common type, allow for easy access to each pallet, which is ideal for businesses with a varied inventory that requires frequent stock rotation. According to the Material Handling Industry of America (MHIA), selective racks account for approximately 60% of the market, underscoring their significance in warehouse operations.

Drive-in racks provide high-density storage by allowing multiple pallets to be stored in a single lane, enhancing space efficiency. This type is best suited for homogeneous products with higher turnover rates. However, it limits access to the items stored deeper in the rack. In a recent report by Grand View Research, it was highlighted that the demand for high-density storage solutions is projected to grow at a CAGR of 6.4% from 2021 to 2028, indicating a robust trend toward optimizing space in warehouses.

On the other hand, cantilever racks are ideal for long or bulky items, making them a versatile option for industries ranging from furniture to building materials.

Push-back racks offer a unique combination of accessibility and storage density, allowing pallets to be stored on a system of nested carts that move backward as new pallets are added. This design enables first-in, last-out (FILO) inventory management, suitable for companies with limited space and varied inventory needs. A survey by the Warehousing Education and Research Council (WERC) reveals that nearly 40% of warehouse operators are focusing on enhancing their storage systems to improve efficiency, further emphasizing the importance of selecting the right type of pallet rack for specific warehouse operational requirements.

Evaluating Your Warehouse Space and Layout Requirements

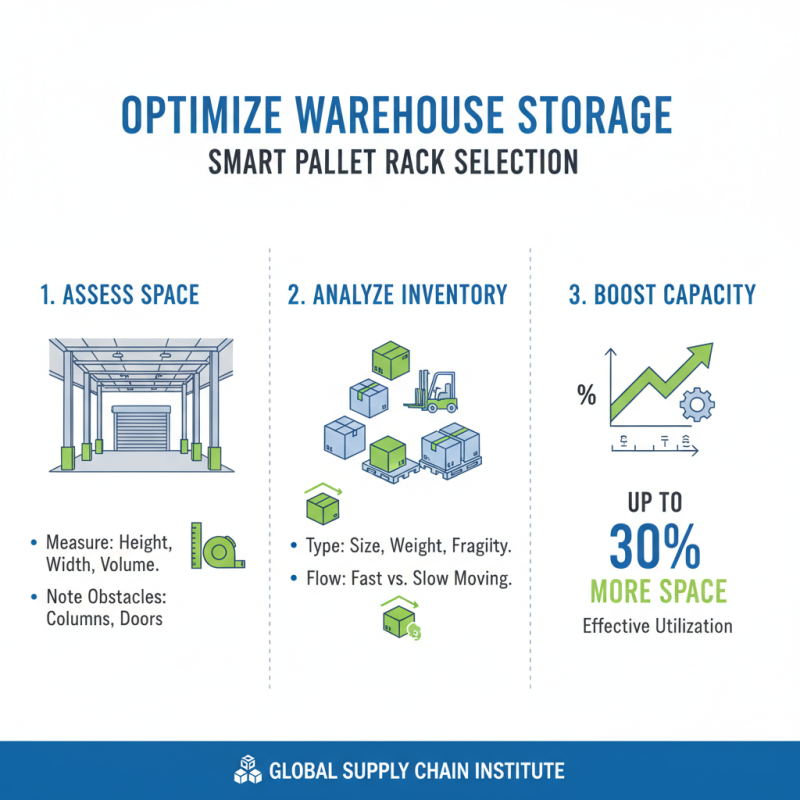

When evaluating your warehouse space and layout requirements for selecting the right industrial pallet racks, it is crucial to accurately assess both the dimensions of the warehouse and the nature of the inventory. The Global Supply Chain Institute estimates that effective warehouse space utilization can improve storage capacity by up to 30%. This highlights the importance of a thorough evaluation before making choices that will affect operational efficiency. Measure the height, width, and overall volume of your space, considering any obstacles such as columns and doors that may impact rack placement.

In addition to physical dimensions, understanding the flow of goods is vital. According to the Warehousing Education and Research Council, optimizing warehouse layout can reduce travel time by up to 20%. Analyzing how items move through the facility allows you to choose racking systems that complement the workflow, whether it’s FIFO (First In, First Out) or LIFO (Last In, First Out). By aligning your pallet rack configuration with your space and layout requirements, you can significantly enhance productivity and minimize costs associated with inefficiencies in your storage system.

Assessing Load Capacity and Weight Distribution Needs

When selecting industrial pallet racks for your warehouse, one of the crucial aspects to consider is load capacity and weight distribution. According to industry reports, improperly assessed load capacities can lead to accidents, product damage, and decreased efficiency. It’s essential to calculate the total weight of goods that will be stored on the racks, including the weight of the pallets themselves. For instance, if the total load exceeds the recommended capacity for a particular rack type, it can compromise the structural integrity and safety of the storage system.

Tips: Always consult with a structural engineer or a warehouse design expert to assess the specific load requirements of your business. They can help determine the optimal design that accommodates not only current inventory but potential growth.

Additionally, understanding weight distribution is vital. Unevenly distributed loads can lead to rack tipping or collapse. Research indicates that loads should be evenly spread out across the racks, keeping heavier items lower and lighter items higher to maintain stability. Utilize load tracking software or inventory management systems that provide insights into your load history and distribution patterns.

Tips: Regularly inspect your pallet racks for signs of wear or damage, particularly after heavy loads are added. Establish a rotation system to ensure that items are stored in a manner that promotes balanced weight distribution across the racking system.

Load Capacity and Weight Distribution of Different Pallet Rack Types

Considering Accessibility and Safety Regulations for Pallet Racks

When selecting industrial pallet racks for your warehouse, prioritizing

accessibility and

safety regulations is crucial. Accessibility ensures that your staff can efficiently handle goods without unnecessary risk or delays. This includes assessing the layout of your warehouse and the type of pallet racks being installed. Consider aisle widths, the height of the racking system, and the ease of access to each level. Properly designed storage systems facilitate smooth movement of forklifts and other machinery, minimizing the likelihood of accidents and promoting a safe working environment.

In addition to accessibility, adherence to safety regulations is paramount. Compliance with local and national standards not only protects your employees but also safeguards your inventory. This involves implementing safety features such as load limits, secure anchoring systems, and regular inspections. Additionally, ensure that your staff is trained in

safe handling practices and aware of emergency protocols related to pallet racks. By integrating accessibility and safety into your pallet rack selection process, you can create a functional and secure warehouse space that supports operational efficiency and worker well-being.

Exploring Cost, Durability, and Maintenance of Various Rack Options

When selecting industrial pallet racks for your warehouse, considering cost, durability, and maintenance is essential for making an informed decision. The initial cost of pallet racks can vary widely depending on the material and design chosen. Steel racks are typically more expensive upfront compared to alternatives like wood or plastic, but they often provide superior strength and longevity, making them a wise investment over time. Evaluating the cost against the expected lifespan and performance can help determine the best option for your budget.

Durability plays a crucial role in the selection process, especially for high-traffic warehouses. Steel racks are less susceptible to damage from heavy loads and impacts, compared to wood, which can warp or break under stress. Additionally, some metal racks come with protective coatings to enhance resistance against corrosion and wear, extending their usable life in challenging environments. Assessing the durability not only impacts long-term costs but also influences safety within the warehouse.

Finally, maintenance is a vital consideration for any rack system. While many steel pallet racks require minimal upkeep due to their strong construction, it's essential to implement routine inspections to ensure structural integrity and safety. Regular maintenance might involve checking for rust, reinforcing connections, and ensuring that weight limits are adhered to. Understanding the maintenance requirements associated with various rack options can significantly influence the overall operational efficiency of your warehouse and minimize unexpected expenses.

Related Posts

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

10 Essential Tips for Maximizing Your Warehouse Mezzanine Space Effectively

-

How to Choose the Right Warehouse Storage Racks for Your Business Needs

-

Top Pallet Racking Solutions in Brisbane for 2025 You Need to Know

-

Why Choose Pallet Racking in Brisbane for Your Warehouse Storage Needs

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More