WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

When it comes to optimizing warehouse space and enhancing operational efficiency, selecting the right industrial pallet racks is crucial. According to John Doe, an expert in warehouse management and storage solutions, "The right pallet rack system can transform a chaotic storage area into a well-organized and highly functional space." This highlights the importance of understanding the specific needs of your warehouse before making a decision.

Industrial pallet racks come in various designs and configurations, each catering to different storage requirements. Factors such as the weight and dimensions of the items being stored, the layout of the warehouse, and the picking methods play a significant role in determining the appropriate rack system. By carefully evaluating these elements, warehouse managers can ensure that their investment in industrial pallet racks supports both current and future operational goals.

In an ever-evolving industry, making an informed choice about industrial pallet racks can lead to increased efficiency, reduced labor costs, and improved inventory management. As experts like John Doe emphasize, investing time and resources into choosing the right system is not just a logistical decision but a strategic move toward sustained success in warehouse operations.

Understanding the Different Types of Industrial Pallet Racks

When selecting the appropriate industrial pallet racks for your warehouse, it’s essential to understand the various types available. The most common type is the selective pallet rack, which allows direct access to every pallet. This system is ideal for warehouses that handle a wide variety of products with minimal height restrictions, as it maximizes flexibility and accessibility.

Selective racks are typically adjustable, allowing users to modify shelf heights according to their inventory needs.

Another popular option is the drive-in pallet rack, which is designed for high-density storage. This type utilizes a system where forklifts can drive directly into the rack structure. The drive-in design minimizes wasted space and is suited for limited product variety, making it perfect for bulk storage where similar items are stored together.

Conversely, the push-back rack offers a mixed approach by allowing forklifts to push pallets back on a sloped track, creating a dynamic system that balances accessibility and compact storage. Understanding these different types can greatly enhance the efficiency and organization of your warehouse operations.

Assessing Your Warehouse Space and Layout Requirements

When considering the right industrial pallet racks for your warehouse, the first critical step is assessing your warehouse space and layout requirements. According to a report by Peerless Research Group, approximately 60% of warehouse operations report inadequate space utilization, leading to inefficient workflows. Understanding your available square footage and the layout, including aisle widths and heights, is essential for selecting racks that maximize storage density while ensuring safe access for personnel and equipment.

The design of your warehouse should accommodate not only the type of products you store but also the operational processes involved in handling those products. A study conducted by AWM (Association of Warehouse Managers) indicates that warehouses optimized with the appropriate racking systems can improve picking efficiency by as much as 30%. For example, if you have a narrow aisle configuration, you might want to consider high-density storage solutions, such as selective racks or drive-in racks, which allow for better spatial management. Additionally, it's vital to account for future growth and flexibility in your layout to avoid costly retrofits when inventory changes or expands. By carefully evaluating these factors, you can ensure your warehouse layout supports both current needs and future scalability.

Warehouse Space Utilization by Pallet Rack Type

Determining Load Capacity and Weight Distribution Needs

When selecting the right industrial pallet racks for your warehouse, understanding load capacity and weight distribution is paramount. According to the Storage Equipment Manufacturers Association (SEMA), proper rack configuration can significantly influence operational efficiency, as improperly loaded racks can lead to structural damage or safety hazards. It's essential to calculate the total weight of the goods that will be stored on the racks, taking into account both individual item weights and the total number of items. For instance, if you plan to store 1,000-pound pallets, the selected racking system must be rated to support this load, plus an additional 20% margin to ensure safety and compliance with industry standards.

Additionally, understanding the height and depth of your racking system is crucial for effective weight distribution. The Warehousing Education and Research Council (WERC) indicates that optimal weight distribution can enhance warehouse operations by maximizing space while minimizing repair and maintenance costs. It is advisable to place heavier items on lower levels of the racks to maintain a low center of gravity, which can help prevent tipping. Detailed assessments of load weight variances and projected growth should be conducted to ensure the chosen racks meet both current and future needs, allowing for the adjustment of storage strategies as inventory demands change.

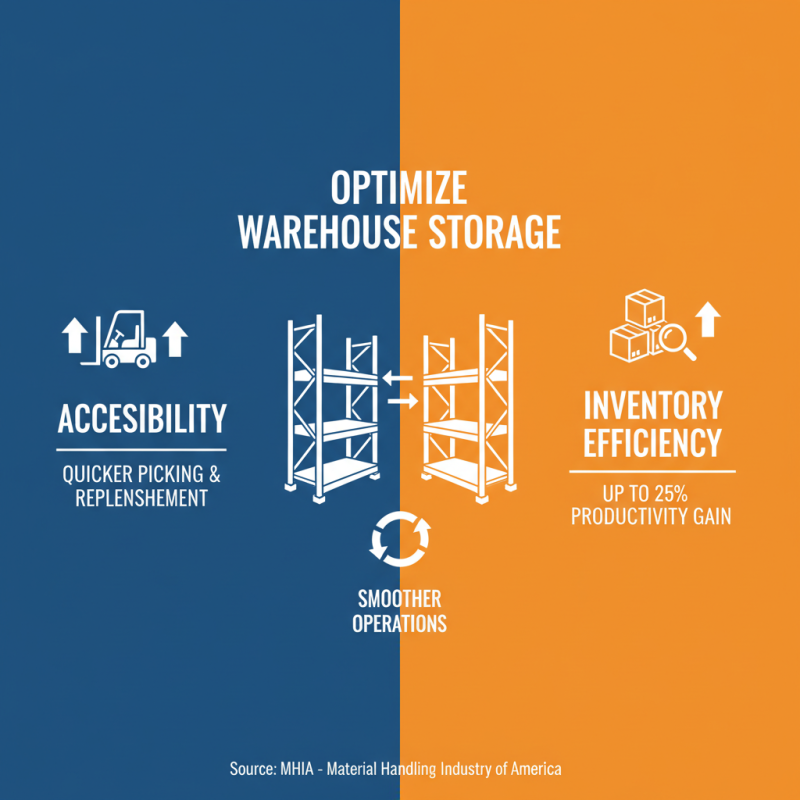

Evaluating Accessibility and Inventory Management Efficiency

When selecting industrial pallet racks for your warehouse, it is essential to prioritize accessibility and inventory management efficiency. According to the Material Handling Industry of America (MHIA), effective inventory management can increase productivity by up to 25%. This improvement often stems from utilizing appropriately designed pallet racks that enhance space utilization and enable smoother access to goods. A well-organized system allows for quicker picking and replenishment, which directly impacts order fulfillment rates.

Accessibility is another crucial factor when evaluating pallet racks. A report from the Warehousing Education and Research Council (WERC) indicates that optimized aisle widths and rack configurations can reduce the time spent locating items by up to 30%. By ensuring that the layout supports operational flow, warehouse managers can significantly minimize downtime and labor costs. Moreover, implementing features such as adjustable shelving and clear labeling systems can further streamline operations, making it easier to track inventory levels and reduce shrinkage. Ultimately, focusing on these aspects not only enhances the overall efficiency of warehouse operations but also contributes to better customer satisfaction through timely deliveries.

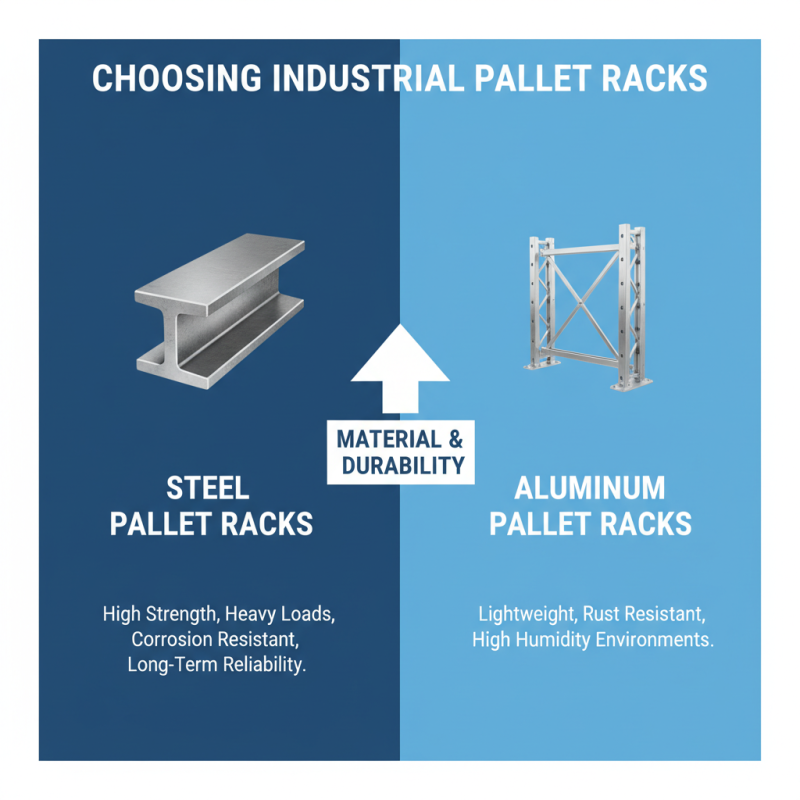

Considering Material and Durability Options for Pallet Racks

When selecting industrial pallet racks for your warehouse, one of the foremost considerations is the material and durability of the racks. Commonly used materials include steel, which is favored for its high strength-to-weight ratio and corrosion resistance. Steel racks can endure heavy loads and provide long-term reliability, making them suitable for environments that involve frequent handling of goods. Alternatively, some companies may opt for aluminum racks, which are lighter and resistant to rust, ideal for environments characterized by high humidity or moisture.

Durability also hinges on the construction and design of the racks. Features such as powder-coated finishes can enhance corrosion resistance, while reinforced designs may offer additional strength to withstand the rigors of daily operations. It's crucial to assess the specific needs of your warehouse, such as load capacity, height requirements, and environmental conditions, to ensure the racks chosen can handle the expected stress over time. Investing in quality materials and robust construction not only helps in safeguarding your inventory but also contributes to overall operational efficiency in the warehouse.

Related Posts

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

-

How to Choose the Right Pallet Rack Beams for Your Warehouse Storage Needs

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

Why Commercial Racking is Essential for Efficient Warehouse Management

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More