WSS Blog

Follow our latest updates and thoughts on our industry10 Best Warehouse Shelving Solutions for Optimal Space Utilization?

In the world of logistics and storage, effective warehouse shelving has become a crucial factor in maximizing space. Industry expert John Smith, who specializes in warehouse operations, emphasizes, “The right shelving can transform how we think about our available space.” This sentiment holds true as businesses strive to optimize their storage capabilities.

When it comes to warehouse shelving, various solutions exist to meet specific needs. Each option varies in design, durability, and capacity. Choosing the right system is not merely a matter of preference; it requires careful assessment of space, inventory, and workflow. A well-organized shelving system can significantly improve efficiency, but it must align with the unique demands of each warehouse.

However, selecting shelving solutions often reveals challenges. Mistakes in calculations or assumptions can lead to wasted space or inefficient layouts. Businesses must reflect on their requirements and embrace trial and error during the implementation process. Ultimately, effective warehouse shelving is not just about stacking items; it’s about creating an environment where every inch counts.

Understanding Warehouse Shelving Needs for Space Optimization

Warehouse shelving is crucial for effective space utilization. Understanding specific shelving needs can significantly enhance efficiency. According to a study by the Warehousing Education and Research Council (WERC), over 30% of warehouse space is underutilized. This statistic highlights the importance of strategic shelving choices.

Different types of shelving meet various storage needs. For example, selective pallet racks are ideal for high-turnover items. They allow easy access, yet they can take up considerable space. In contrast, drive-in racks maximize storage capacity but may complicate inventory management. These choices require careful consideration of the unique dynamics of each warehouse.

Moreover, many facilities struggle with poor organization. Inadequate labeling and unclear pathways can lead to wasted time. Research shows that inefficient layouts can increase operational costs by up to 20%. This data compels decision-makers to regularly assess and refine shelving strategies. Inadequate planning for growth can also lead to bottlenecks in operations. An ongoing evaluation is essential for sustained success.

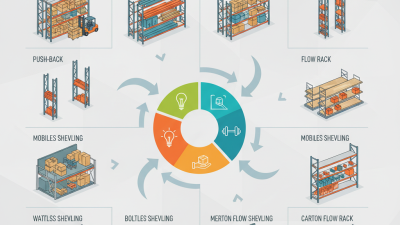

Types of Warehouse Shelving Solutions and Their Features

Warehouse shelving solutions are pivotal for effective space utilization. Various types can meet diverse needs. For example, selective shelving is common and offers direct access to all pallets. It’s suitable for high-traffic areas. According to industry reports, 65% of warehouses favor selective shelving for its ease of use.

Drive-in shelving maximizes vertical space. This style allows forklifts to enter the racks, storing pallets in deep lanes. It is efficient for bulk storage but can limit individual item access. Research shows that this method can increase storage capacity by 40%. Consider flow rack systems as well. They use gravity to move items, which enhances picking speed during order fulfillment.

Tips: Assess your storage volume before choosing a type. Visualize what items will occupy your shelves. Ensure accessibility for efficient workflow. Do not overlook the importance of weight capacity. Not all shelving is built for heavy loads. A misjudgment here could lead to accidents or damages. Regularly review your shelving strategy; needs might change over time. Adaptability is key for optimizing warehouse operations.

Comparative Analysis of Adjustable vs. Fixed Shelving Systems

When deciding between adjustable and fixed shelving systems, it's essential to consider your specific needs.

Adjustable shelving offers flexibility. You can change the height and width easily. This adaptability is great for warehouses that store various items.

However, it can be less stable if not installed correctly. Customized heights might lead to overloaded shelves.

Fixed shelving, on the other hand, provides a sturdy structure. This system is great for items that are consistently sized. Over time, it can help maintain organization.

Yet, it lacks the versatility of adjustable options, which can be limiting. Once installed, it’s challenging to change the layout.

Companies often face the dilemma of needing space for growth while wanting something robust.

In warehouse settings, choosing the right shelving solution can lead to better efficiency. Reflecting on your inventory will help.

If your stock changes frequently, adjustable can be more advantageous. However, if your items are static, fixed shelving may serve you better.

Each choice has its merits and drawbacks. Assessing your specific circumstances is crucial.

Maximizing Vertical and Horizontal Space with Innovative Designs

Maximizing vertical and horizontal space is crucial in any warehouse setting. Innovative shelving designs can significantly improve efficiency. For example, tall shelving units can utilize vertical space that often goes unused. They create more room for products, freeing up floor space. Mobile shelving units are another great option. They can be relocated as needed, adapting to changing inventory requirements.

**Tip:** Always measure your ceiling height before installing tall shelves. This helps avoid wasted space and ensures safety. Think about your inventory types too. If you store heavy items, choose sturdy shelves.

Consider implementing multi-level shelving. This can double your storage capacity without expanding your footprint. However, it requires careful planning to ensure accessibility. Adjustments may be needed if items don’t fit as expected.

**Tip:** Regularly assess your shelving layout. Are items easy to reach? Is space being used efficiently? If not, it’s time to rethink your strategy. Embracing a dynamic configuration can lead to significant improvements in space utilization.

Best Practices for Organizing Inventory on Warehouse Shelving Systems

Effective organization on warehouse shelving systems is crucial for maximizing space. A study from the Warehousing Education and Research Council notes that proper shelving can increase storage efficiency by up to 30%. This means better use of available space leads to more accessible inventory. It’s essential to categorize items by size, weight, and frequency of access. Heavier items should be placed on lower shelves to prevent accidents. Regular rotation of stock is also necessary, especially for perishable goods.

Creating a clear labeling system is vital. Color-coded labels can make identifying items quicker. A report by the Material Handling Industry highlights that mislabeled inventory can lead to a loss of productivity. Many warehouses still struggle with maintaining an organized system. Relying solely on memory for item placement can lead to errors. Regular audits can help reassess inventory organization. However, some methods may become outdated quickly, leading to inefficiencies. Continuous education and adaptation are key for keeping shelving practices effective.

Related Posts

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

2025 How to Optimize Your Warehouse with Commercial Racking Solutions

-

What are the Best Commercial Racking Systems for 2026?

-

Top 10 Racking and Shelving Systems for Efficient Storage Solutions?

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More