WSS Blog

Follow our latest updates and thoughts on our industry10 Best Commercial Racking Systems for Maximizing Storage Efficiency?

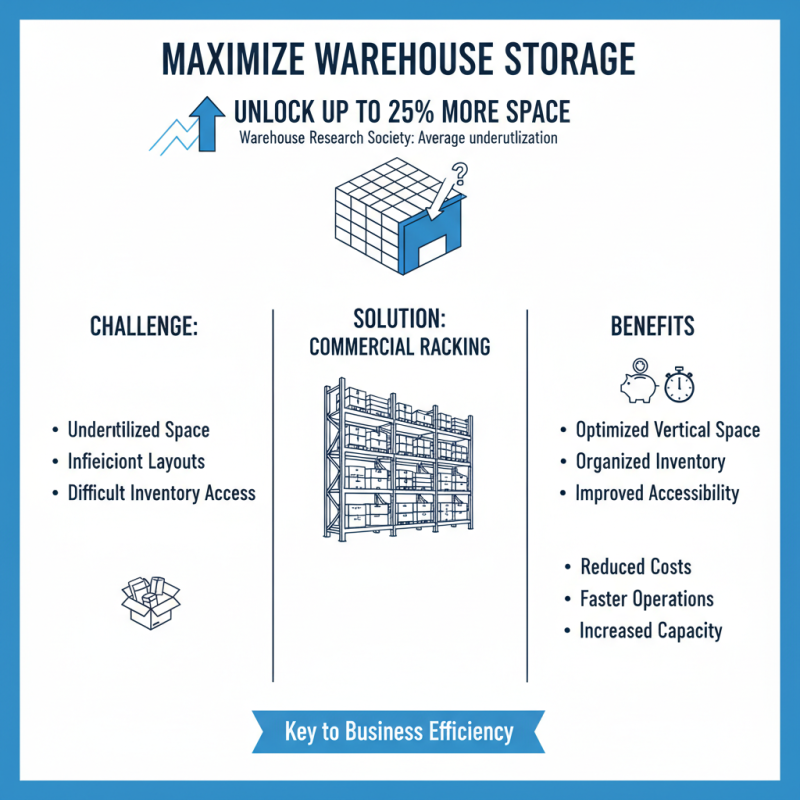

In today's fast-paced business environment, maximizing storage efficiency is crucial. Commercial racking systems play a vital role in achieving this. They help organize inventory effectively while optimizing space. The right racking system can significantly reduce clutter and improve workflow. However, choosing the best solution can be challenging.

Many businesses overlook the importance of selecting the right commercial racking. This often leads to wasted space and inefficiencies. Some systems may not accommodate future growth, which can hinder operations. It’s essential to assess your specific storage needs carefully. Not all racking systems are created equal.

Consideration of various factors is important, including load capacity and accessibility. Visualizing your ideal layout can help you make informed decisions. Remember, it’s not just about storage; it’s about efficiency. The goal is to streamline your operation. A well-planned commercial racking system can lead to a significant return on investment. Reflecting on your current setup is key to finding areas for improvement. Choosing wisely can transform your storage capabilities.

Types of Commercial Racking Systems Available for Storage Solutions

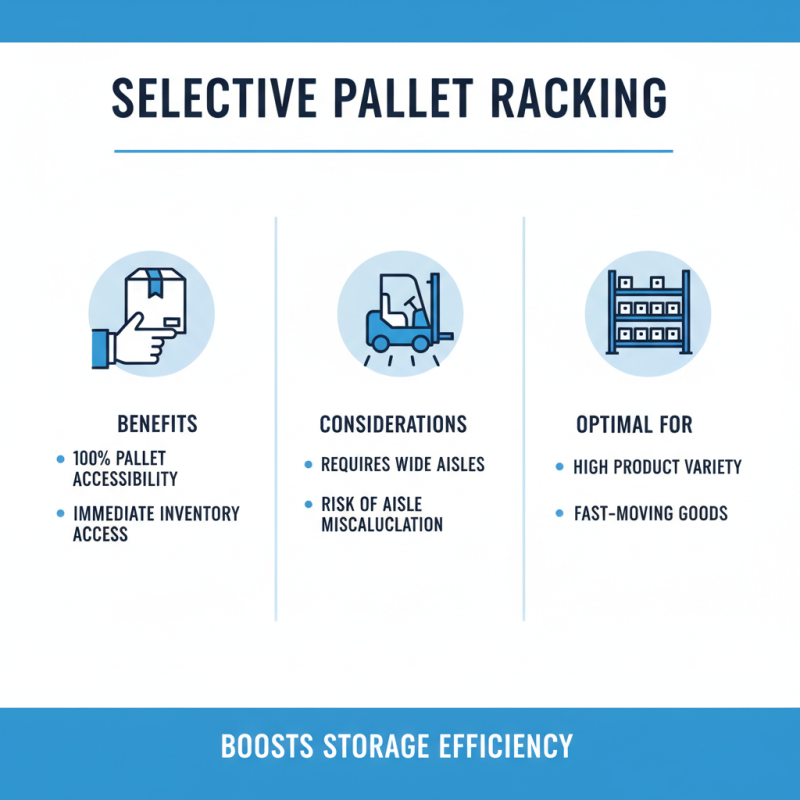

When considering commercial racking systems, various types are available to enhance storage efficiency. Selective pallet racking is one of the most common types. It allows immediate access to all pallets. This means better inventory management. However, it requires adequate aisle space. Miscalculating aisle width can lead to accessibility issues.

Another option is drive-in racking. This system maximizes space by allowing multiple pallets to be stored in a single lane. It can be great for bulk storage. Yet, it limits access to products at the back. Planning is crucial, as inventory rotation can suffer if not managed well.

For businesses with unique needs, cantilever racking provides flexibility. It handles long or bulky items effectively. Still, this system can be more expensive compared to others. Evaluating space, inventory, and costs is vital. Each racking system has its pros and cons, requiring careful consideration to achieve the best storage solution.

Factors to Consider When Choosing a Racking System for Your Business

When selecting a racking system, consider your specific storage needs. Reflect on the types of items you will store. Some items require more vertical space, while others need width. Your inventory's weight is also crucial. Heavier items need sturdier racks.

Assess the layout of your warehouse. Is it spacious or compact? A narrow aisle layout may work best for high-density racks. Think about accessibility, too. Employees should be able to retrieve items quickly. It’s essential to balance space efficiency and ease of access.

Budget constraints are another factor. Some systems are more cost-effective than others, but sometimes cheaper options compromise quality. Investing in a system that meets your long-term needs might save costs in the future. Regular assessments of your racking system’s performance will lead to improvements. Keep asking: is this the best choice for my business?

10 Best Commercial Racking Systems for Maximizing Storage Efficiency

Benefits of Efficient Racking Systems in Warehouse Operations

Efficient racking systems play a vital role in warehouse operations. They maximize storage space and streamline inventory management. A well-designed system can significantly boost productivity. Workers can locate items quickly. This reduces the time spent searching.

When considering racking systems, think about your specific needs. Measure your space carefully. Choose a design that allows for easy access to goods. Avoid overcrowding. It may be tempting to fit in more, but it can hinder efficiency.

**Tip:** Regularly assess your racking system’s effectiveness. Adjust layouts as inventory changes. Train staff on best practices for loading and unloading. Encourage open communication. Workers should feel comfortable suggesting improvements. Sometimes, a small change can create a big impact.

The right racking solution simplifies operations. It reduces mishaps during picking. It also keeps products organized and safe. Ensure there's enough space between aisles. This may seem trivial, but it can enhance safety and workflow. A thoughtful layout can transform a cramped warehouse into an efficient space.

Top 10 Commercial Racking Systems for Optimal Space Utilization

Maximizing storage efficiency is essential for businesses looking to optimize space usage. According to the Warehouse Research Society, about 25% of warehouse space is often underutilized. This statistic underscores the importance of robust commercial racking systems. Effective racking solutions can transform wasted space into functional storage areas, allowing easy access to inventory.

Different types of racking systems serve various purposes. Selective pallet racks are popular for high-density storage, while drive-in systems offer deeper storage options. Each system can maximize vertical space, freeing up floor area. A study by Logistics Management showed that companies adopting efficient racking practices reported a 15% increase in productivity. However, not everyone invests in the right racking solutions. Many businesses overlook layout optimization, which can lead to a chaotic storage environment.

Inadequate planning can result in disorganized inventory and wasted time. It's crucial to regularly assess storage solutions and adapt to changing needs. The correct racking system could significantly improve logistics operations. Yet, adjustments are often disregarded until after inefficiencies cause delays. Recognizing these shortcomings is vital to reap the benefits of optimal space utilization and increase overall operational efficiency.

Maintenance Tips for Ensuring Longevity of Racking Systems

Maintaining racking systems is crucial for any warehouse or storage facility. Regular inspections should be performed to identify wear and tear. Look for signs of rust, bent frames, or loose bolts. Small issues can escalate quickly. Noticing them early can save time and money.

Cleaning racking systems is often overlooked. Dust and debris can accumulate, leading to potential hazards. A simple wipe-down with a damp cloth can maintain clarity and prevent rust. It’s essential to ensure that all items are stored correctly. Improper loading can cause instability. Employees should be trained in proper stacking techniques.

Periodic maintenance checks are necessary. Schedule these every few months to ensure everything remains intact. Consider checking load capacities regularly, as they may change over time. Investing in preventative measures pays off. A well-maintained racking system not only enhances safety but also boosts overall efficiency. Ignoring these aspects could have lasting consequences. In the long run, the health of the racking system relies heavily on consistent attention.

10 Best Commercial Racking Systems for Maximizing Storage Efficiency

| Racking System Type | Max Load Capacity | Best For | Key Features | Maintenance Tips |

|---|---|---|---|---|

| Selective Pallet Racking | 3,000 lbs / pallet | Warehouses | Adjustable, easy access | Regular inspections for damage |

| Drive-In Racking | 5,000 lbs / pallet | High density storage | LIFO storage method | Check for alignment and wear |

| Push Back Racking | 2,000 lbs / pallet | FIFO storage | Space efficiency | Inspect lanes and pushback carts |

| Cantilever Racking | 3,500 lbs / arm | Long items | Versatile design | Check stability and secure loads |

| Multi-Tier Racking | 1,500 lbs / shelf | Small parts | Space maximization | Regular cleaning and organization |

| pallet Flow Racking | 1,800 lbs / pallet | Rotating inventory | Gravity-fed system | Ensure wheels are functioning |

| Steel Shelving | 600 lbs / shelf | Office storage | Durable and long-lasting | Wipe down regularly |

| Mezzanine Racking | Varies based on design | Maximize vertical space | Additional deck space | Inspect for stability and supports |

| Heavy-Duty Racking | 4,000 lbs / pallet | Heavy materials | Reinforced structure | Check welds and connections |

| Flow Rack | 1,200 lbs / lane | Fast-moving inventory | FIFO method | Keep lanes clear and clean |

Related Posts

-

How to Choose the Right Storage Racking for Your Warehouse Needs?

-

2026 Best Storage Racking Solutions for Your Warehouse Needs?

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

Ultimate Guide to Dexion Pallet Racking Solutions for Your Warehouse

-

2025 How to Optimize Your Warehouse with Commercial Racking Solutions

-

Top 10 Racking and Shelving Systems for Efficient Storage Solutions?

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More