WSS Blog

Follow our latest updates and thoughts on our industryWhat are the Best Commercial Racking Systems for 2026?

In a rapidly evolving market, choosing the right commercial racking system has become crucial for businesses. Companies increasingly seek efficiency and durability. The right racking can transform a warehouse's layout. It maximizes space and improves workflow. However, not all systems suit every operation.

As we approach 2026, various factors influence the best choices. Steel systems offer strength, while adjustable options provide flexibility. Selecting a system requires assessing individual needs and growth potential. Yet, many businesses make hasty decisions based on trends, overlooking long-term benefits.

Understanding the various commercial racking systems available will help enhance operational efficiency. Thoughtful assessments of strengths and weaknesses can guide decisions. Ignoring this can lead to poor investments and wasted space. As we navigate the future, careful consideration will determine which systems will stand the test of time.

Emerging Trends in Commercial Racking Systems for 2026

As we approach 2026, the landscape of commercial racking systems is evolving rapidly. One prominent trend is the increased focus on sustainability. Businesses are now seeking to reduce their environmental impact. This includes using recyclable materials in racking designs. Lightweight metals and eco-friendly composites are gaining traction. Companies are looking for systems that offer both durability and a smaller carbon footprint.

Another trend is the integration of smart technology. Racking systems are being equipped with IoT sensors. These sensors monitor inventory levels in real-time. This innovation helps businesses manage space more efficiently. However, the complexity of these systems can be daunting. Not every business is ready to adopt this technology. Staff training and system maintenance can pose challenges.

Moreover, customization is on the rise. Businesses want racking solutions tailored to their unique needs. Modular designs allow for flexibility in configuration. But, this approach can sometimes lead to over-engineering. Striking the right balance between flexibility and simplicity is crucial. As innovation continues, it will be interesting to see how these factors shape the future of commercial racking systems.

What are the Best Commercial Racking Systems for 2026? - Emerging Trends in Commercial Racking Systems for 2026

| Racking System Type | Load Capacity (lbs) | Material | Adaptability | Typical Application |

|---|---|---|---|---|

| Selective Racking | 2,500 - 6,000 | Steel | High | General storage |

| Drive-In Racking | 3,000 - 5,000 | Steel | Moderate | High-density storage |

| Mobile Racking | 2,000 - 4,000 | Steel/Aluminum | Very High | Space-saving |

| Pallet Flow Racking | 2,500 - 3,000 | Steel | Moderate | FIFO inventory |

| Cantilever Racking | 1,000 - 10,000 | Steel | High | Long, bulky items |

Key Features to Consider When Choosing Racking Systems

When selecting a racking system for 2026, several key features demand attention. First, consider the storage density. According to recent industry reports, maximizing vertical space can increase storage capacity by up to 40%. This can lead to significant cost savings. Research from logistics firms suggests that high-density systems, like selective or drive-in racks, are becoming increasingly popular in warehouses.

Next, evaluate the adaptability of the system. Flexible racking allows for quick adjustment to changing inventory needs. A study indicated that companies using modular systems report 30% faster inventory turnover. This adaptability is crucial as market demands shift rapidly. Durability is another factor. Research shows that well-built racks can last for over a decade with minimal wear. However, it's essential to routinely inspect racking systems. Neglect can lead to safety hazards, impacting both efficiency and compliance.

Lastly, safety features should not be overlooked. Systems with integrated safety mechanisms reduce damage risks and promote a safer working environment. About 25% of warehouse accidents are linked to poor racking installations, highlighting the need for careful consideration. Investing in safety-first designs can build a resilient warehouse infrastructure that withstands the challenges of future demands.

Best Commercial Racking Systems for 2026

Top Commercial Racking Systems Recommended for Various Industries

When assessing commercial racking systems for various industries in 2026, the focus shifts to adaptability and efficiency. Industries such as warehousing, retail, and manufacturing require systems that enhance storage and improve workflow. According to a 2023 report from Warehouse Optimization Strategies, nearly 75% of companies prioritize space efficiency due to rising operational costs. This highlights the need for innovative racking solutions.

Pallet racking systems remain a staple in warehousing. They provide flexibility for different load sizes and types. Mobile shelving systems are becoming popular in retail settings. These systems allow for easy access and can be adjusted based on inventory changes. However, their mobility can sometimes lead to structural concerns if not properly maintained, reflecting a need for ongoing evaluations of safety standards.

In the manufacturing sector, cantilever racking is gaining traction. It effectively stores longer items like pipes and lumber. An industry survey indicated that 60% of manufacturers plan to invest in cantilever systems by 2026. However, without proper planning, space wastage can occur. Ensuring compatibility with other storage solutions is crucial. Each industry has unique challenges that must be considered when choosing the best racking systems.

Sustainability Practices in Commercial Racking Solutions for 2026

As we look toward 2026, sustainability in commercial racking systems takes center stage. Businesses face increasing pressure to adopt eco-friendly practices. Choosing materials that are recyclable and sourced responsibly is now a priority. Many facilities are turning to steel and other metals, which can be recycled at the end of their life cycle. This shift reduces waste and aligns with global environmental goals.

The design of racking systems is evolving. Modular designs allow for flexibility and adaptability. These systems minimize the use of materials while maximizing storage capacity. However, balancing functionality with sustainability is challenging. Some companies still prioritize low initial costs over long-term environmental impact. It’s essential to consider how racking systems can contribute to overall operational sustainability.

Energy efficiency is another critical aspect of these solutions. LED lighting integrated into racking units reduces energy consumption. Yet, some businesses hesitate to invest in high-tech options due to upfront expenses. Reflecting on these decisions is crucial for future growth.

We must ask ourselves: Are we truly committed to sustainability, or are we merely following trends?

Future Innovations to Watch in Racking Technology and Design

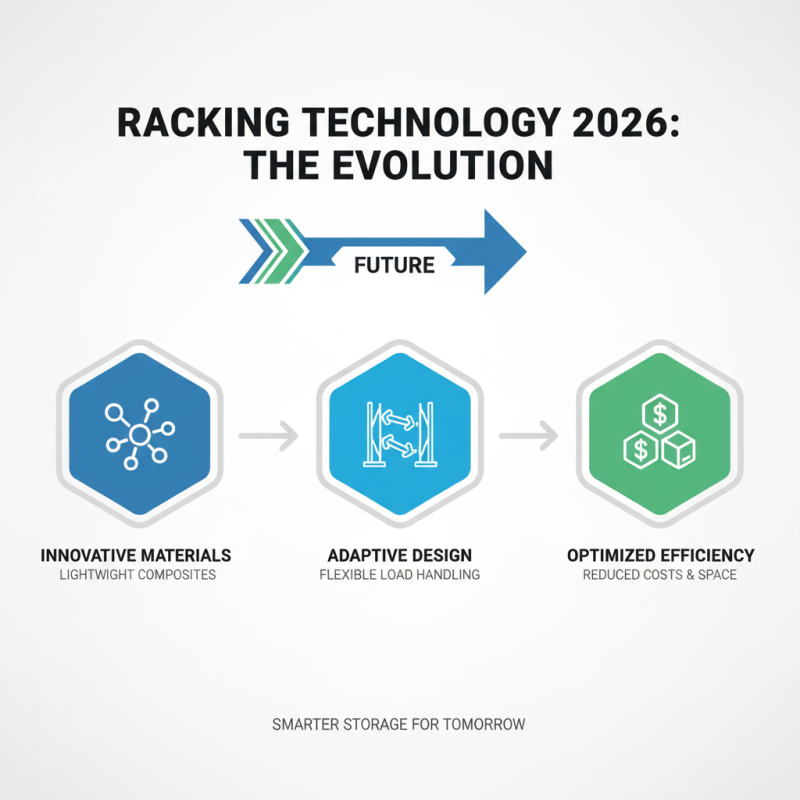

As we look towards 2026, the landscape of racking technology is poised for significant change. Innovative materials will play a vital role. Lightweight composites could replace traditional metals, enhancing flexibility and reducing costs. Imagine racks that adapt to varying load demands seamlessly, maintaining stability while optimizing space.

Automation is another key area. Automated storage and retrieval systems will likely become more prevalent. These systems can increase efficiency in handling inventory. Visualizing a warehouse where machines do the heavy lifting brings excitement. Yet, reliance on such technology raises questions about job displacement and maintenance.

Sustainability is also a critical focus. Eco-friendly designs will emerge, incorporating recyclable materials. However, implementing these changes may pose challenges. Will companies prioritize sustainability over cost? The balance between innovation and practicality is a continuous struggle in racking systems. As we embrace the future, these unresolved issues will inevitably shape the racking industry.

Related Posts

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

2025 How to Optimize Your Warehouse with Commercial Racking Solutions

-

How to Choose the Right Pallet Rack Beams for Your Warehouse Storage Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More