WSS Blog

Follow our latest updates and thoughts on our industryTop Benefits of Industrial Racking Solutions for Your Warehouse Needs?

Warehouse efficiency is crucial for any business aiming for growth. Industrial racking solutions offer an effective way to maximize space and improve organization. These systems are designed to accommodate various storage needs. They can significantly increase your storage capacity while ensuring easy access to items.

Consider the vertical space in your warehouse. Industrial racking systems can utilize that height efficiently. They allow for better inventory management and reduced clutter. However, choosing the right solution requires careful planning. Each warehouse has unique challenges, and racking systems must fit those needs specifically.

It's important to reflect on potential limitations as well. Not all racking solutions are suitable for every product. Some may compromise safety if not installed correctly. Understanding the benefits and drawbacks will lead to better decisions. Finding the right balance is essential for optimizing warehouse operations.

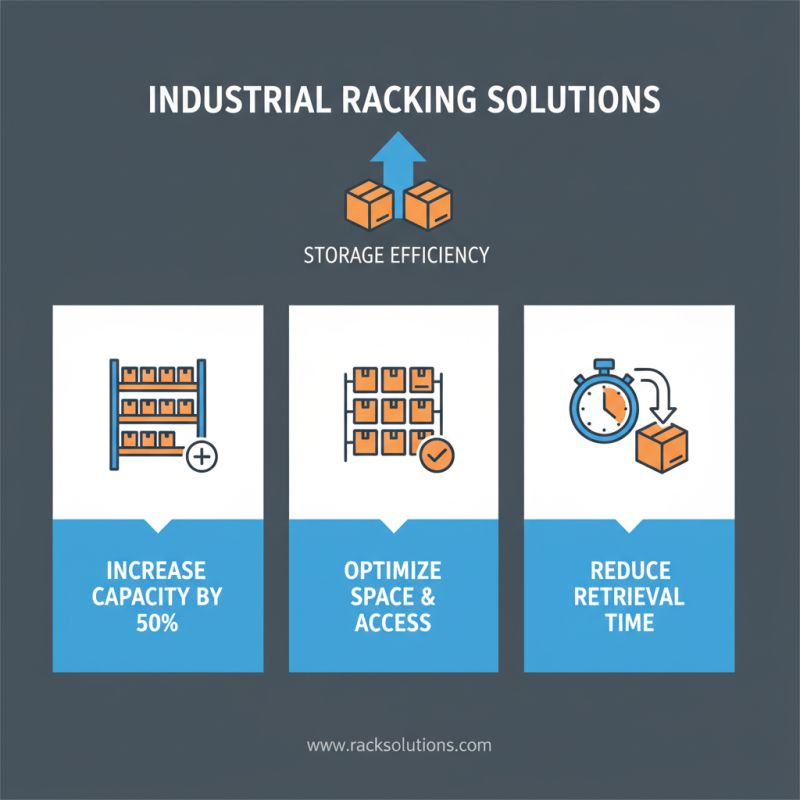

Benefits of Increased Storage Efficiency with Industrial Racking Solutions

Industrial racking solutions significantly enhance storage efficiency in warehouses. Effective racking can increase storage capacity by up to 50%, allowing businesses to make better use of available space. A well-organized racking system minimizes wasted space, enabling easier access to products and reducing retrieval time.

According to a recent study by the Warehousing Education and Research Council (WERC), over 65% of warehouse operations face challenges with inefficient storage layouts. This inefficiency often leads to higher operational costs. Racking systems can optimize the use of vertical space, ensuring that every square foot serves its purpose. Some companies have reported reducing storage costs by 10-14% after implementing proper racking systems.

While investing in racking solutions can be beneficial, not all setups yield immediate results. Improper design can lead to safety issues or equipment damage. Regular assessments and adjustments to the racking configuration may be necessary to keep up with changing inventory needs. Businesses must remain vigilant and periodically review their racking effectiveness to ensure optimal performance.

Cost-Effectiveness of Implementing Racking Systems in Warehouses

Implementing racking systems in warehouses has notable cost benefits. These systems optimize space, allowing you to store more goods in less area. When you increase storage capacity, you reduce the cost per square foot of your warehouse. This efficiency can lead to significant savings over time, especially for businesses with high turnover rates.

However, it's important to consider the initial investment. Some racking systems can be costly. This may discourage smaller businesses from upgrading. Yet, over time, the return on investment becomes apparent. Properly organized inventory reduces picking times and improves operational flow, leading to better customer satisfaction. A well-structured warehouse means fewer errors and less wasted time.

While the benefits are clear, the challenge lies in selecting the right system. Not every racking solution suits every warehouse. Assessing the specific needs is essential. You may need to revisit your choices and adapt to the changing demands of your operations. Achieving cost-effectiveness requires ongoing evaluation and adjustments. The ideal system today might not be adequate tomorrow.

Top Benefits of Industrial Racking Solutions for Your Warehouse Needs

This chart illustrates the cost-effectiveness of implementing racking systems in warehouses by showcasing the percentage of space utilization, efficiency improvements, and reduction in operational costs associated with various racking solutions.

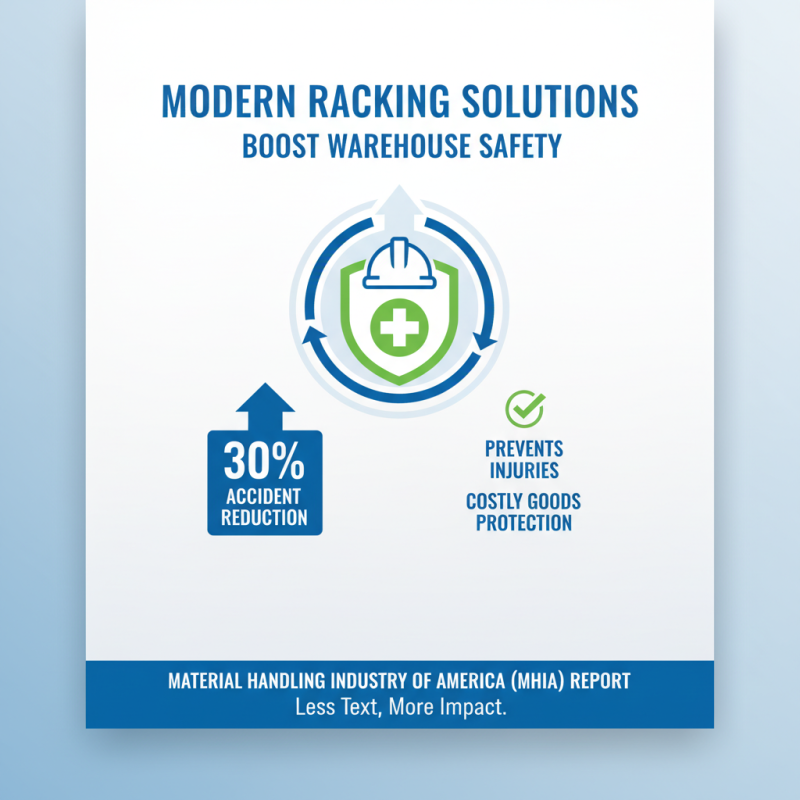

Enhanced Safety Measures Offered by Modern Racking Solutions

Modern racking solutions significantly enhance warehouse safety. According to a recent report by the Material Handling Industry of America (MHIA), proper racking can reduce workplace accidents by up to 30%. This is crucial in environments where heavy goods are stored and retrieved daily. By implementing sturdy and well-designed racking systems, warehouses can prevent costly injuries.

Enhanced safety measures include features like load limits, seismic bracing, and adjustable shelving. These measures ensure that racking systems can tolerate heavy loads. Studies indicate that over 25% of workplace injuries involve improper lifting and falling objects. Racking systems minimize these risks by promoting better organization and allowing easy access to items.

However, not all racking systems are created equal. Some may lack durability or stability. Choosing the right material and design is essential. Regular maintenance and inspections can also be overlooked, leading to potential safety hazards. It's crucial for warehouse managers to continually assess these systems, ensuring they meet the evolving needs of the workforce.

Flexibility and Scalability of Industrial Racking for Growing Needs

In the fast-paced world of warehousing, flexibility is essential. Industrial racking solutions offer various options to meet changing demands. Businesses often face challenges in handling fluctuating inventory levels. Having an adjustable racking system can make a significant difference.

Scalability is another critical advantage. As businesses grow, they require more storage space. Modular racking designs allow easy expansion. You can simply add more sections without disrupting existing layouts. This adaptability helps companies respond quickly to market needs. However, it requires thoughtful planning. Poor layout choices can lead to wasted space.

Furthermore, not all racking options work for every business. Each warehouse has its unique challenges. It's crucial to evaluate specific needs before implementing a solution. A mismatch can hinder efficiency rather than enhance it. Regular assessment of storage and retrieval processes is vital. It ensures that the chosen racking system continues to support growth effectively.

Top Benefits of Industrial Racking Solutions for Your Warehouse Needs

| Benefit | Description | Impact on Warehouse Efficiency |

|---|---|---|

| Flexibility | Ability to easily adapt layout according to changing storage needs. | Increased operational efficiency through optimal space utilization. |

| Scalability | Seamless addition of more racking systems as inventory grows. | Supports business growth without requiring significant reconfiguration. |

| Improved Access | Enhanced design for reaching products quickly and safely. | Reduces time spent retrieving items, boosting productivity. |

| Cost-Efficiency | Minimizes warehouse overhead through optimized space and resources. | Cost savings allow for reinvestment in other business areas. |

| Safety | Reduction in accidents and product damage with structured storage. | Creates a safer working environment leading to fewer insurance claims. |

Improved Inventory Management and Accessibility through Racking Systems

Efficient inventory management is vital for any warehouse operation. Racking systems enhance this by maximizing vertical space. This allows warehouses to store more products without expanding the footprint. When items are properly stored, accessibility improves. Workers can quickly locate and retrieve products. Time is saved, which can lead to increased productivity.

However, there are challenges. Poorly designed racking can lead to confusion. Employees may struggle to find items, resulting in delays. Regular audits are necessary to maintain organization. Identifying which products move fastest can help optimize layout. Sometimes, it’s easy to overlook small details, like labeling.

Creating a user-friendly racking system is essential. Clear signage and designated spaces improve workflow. As inventory changes, adjustments may be needed. This requires ongoing evaluation to adapt to new needs. Without proactive management, even the best systems can become inefficient over time.

Related Posts

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

What are the Best Commercial Racking Systems for 2026?

-

Top 10 Racking and Shelving Systems for Efficient Storage Solutions?

-

10 Best Warehouse Shelving Solutions for Optimal Space Utilization?

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

How to Choose the Right Heavy Duty Pallet Racks for Your Warehouse Needs?

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More