WSS Blog

Follow our latest updates and thoughts on our industryTop Benefits of Cantilever Racking for Warehouse Storage Solutions?

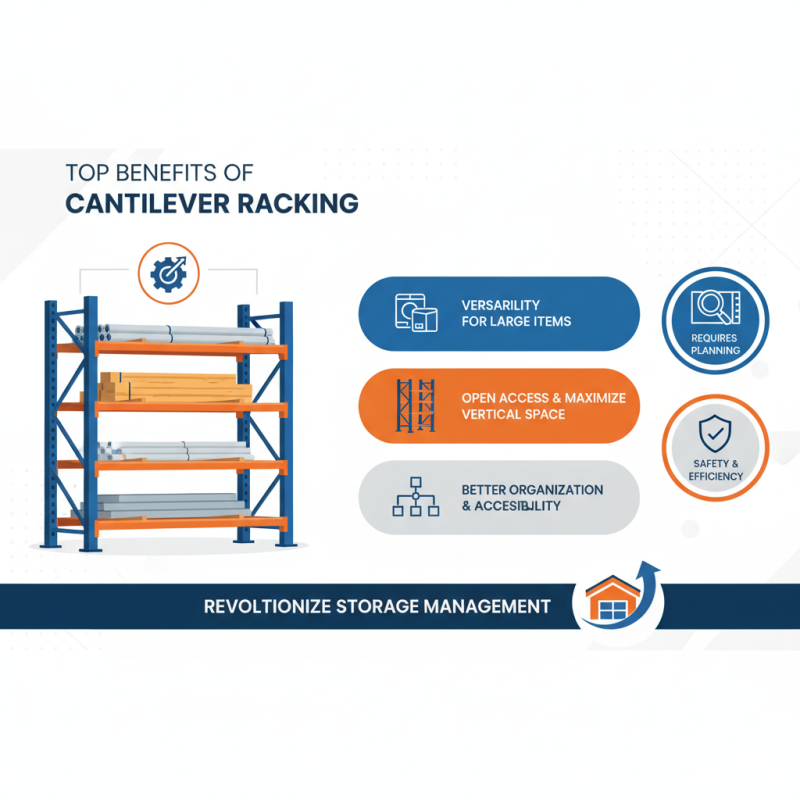

In modern warehouse operations, effective storage solutions are crucial. Daniel Marks, a leading expert in warehouse management, states, “Cantilever racking offers unmatched versatility for large items.” This statement reflects the essence of cantilever racking and its unique benefits.

Cantilever racking is designed to store long and bulky items. These systems provide open access and maximize vertical space. This is especially valuable for warehouses with diverse inventory types. Yet, some warehouses overlook the potential of this storage method. It requires careful planning to ensure safety and efficiency.

Ultimately, adopting cantilever racking can revolutionize storage management. It allows for better organization and accessibility. However, inadequate setup can lead to inefficiencies and potential hazards. Understanding these aspects is critical for any operation considering cantilever racking.

Overview of Cantilever Racking Systems in Warehousing

Cantilever racking systems offer a versatile solution for warehouses. They are designed for storing long, bulky items such as lumber, pipes, or furniture. The adjustable arms make it easy to accommodate various sizes. This flexibility can be critical for businesses with changing inventory needs.

These racks maximize vertical space, allowing for higher storage and better organization. A well-organized warehouse can lead to increased efficiency. However, poor planning can lead to wasted space. The placement of the racks should be carefully considered. If not done properly, obtaining items could become a hassle.

Safety is another concern. Proper installation and regular maintenance are essential. If arms are overloaded, the system can become unstable. Regular checks can mitigate this risk. It’s essential to train staff on how to use the equipment safely. The strength of cantilever racking comes with responsibilities.

Top Benefits of Cantilever Racking for Warehouse Storage Solutions

Key Advantages of Cantilever Racking for Various Industries

Cantilever racking is a versatile storage solution used across multiple industries. Its design allows for the efficient storage of long, bulky items. This is particularly beneficial in sectors like manufacturing, construction, and retail. According to a report by the Warehouse Management Association, implementing cantilever racking can increase warehouse space usage by up to 40%. This figure is striking, emphasizing the value of maximizing storage capabilities.

Industries handling pipes, lumber, and appliances benefit greatly from this system. With cantilever racks, products are easily accessible and organized. A survey conducted by the Material Handling Industry Association revealed that 75% of warehouses report improved picking times after installing cantilever racking. However, it’s essential to consider the impact of improper use. Inadequate weight distribution can lead to safety hazards and asset damage. Regular inspections and training for staff can mitigate these risks.

These racks can also be tailored to specific needs. Flexible sizes and configurations allow for adapting to various product dimensions. Yet, customization may lead to unexpected costs or delays. Some users find the initial investment significant, which can raise questions about long-term benefits. Balancing initial costs with improved efficiency is a crucial consideration for decision-makers.

Space Optimization: Maximizing Warehouse Storage Efficiency

Cantilever racking is a game changer for warehouse storage. It maximizes vertical space, allowing for efficient use of height. This design is ideal for storing long or bulky items. It eliminates wasted floor space, accommodating various product dimensions. With the right setup, a warehouse can increase its storage capacity significantly.

In many warehouses, traditional shelving can limit accessibility. Cantilever systems provide clear access to items. This can lead to quicker retrieval times. However, careful planning is essential when designing the layout. For example, the aisles must be wide enough for forklifts. Miscalculations can result in storage inefficiencies.

Moreover, the structure requires regular maintenance to ensure safety. This often gets overlooked during busy periods. Workers might hurry through routines, which can lead to accidents. Investing in proper training and safety checks is crucial. While cantilever racking offers great benefits, these aspects need attention to maximize their potential.

Top Benefits of Cantilever Racking for Warehouse Storage Solutions

| Benefit | Description | Expected Impact |

|---|---|---|

| Space Optimization | Cantilever racks utilize vertical space efficiently, allowing for taller storage and better organization. | Increased storage capacity by up to 40%. |

| Flexibility | Adjustable arms can accommodate various sizes of products easily. | Ability to adapt to different inventory needs. |

| Improved Accessibility | Open design allows for easier access to stored items. | Reduced retrieval time by 30%. |

| Enhanced Durability | Designed to handle heavy loads and withstand warehouse conditions. | Lower replacement costs due to longer lifespan. |

| Cost-Effectiveness | Maximizes storage without needing extensive renovations. | Savings on construction and operational costs. |

Enhanced Accessibility and Organization with Cantilever Racking

Cantilever racking significantly enhances warehouse accessibility and organization. It offers a flexible storage solution, especially for long and bulky items. According to industry reports, proper racking systems can improve warehouse space utilization by up to 30%. This allows businesses to store more products efficiently, reducing overhead costs.

The open design of cantilever racks ensures items are easily visible and accessible. Employees spend less time searching for products. A study indicated that improved accessibility can boost picking speed by nearly 50%. However, it’s vital to ensure that these systems are properly maintained. Neglected racking can lead to safety hazards and reduced efficiency.

Another factor to consider is the variability in load requirements. While cantilever racks are adaptable, not all configurations are suitable for every product type. Regular assessments and adjustments are crucial. Balancing storage and safety will ultimately define the effectiveness of cantilever racking in any warehouse setting.

Cost-Effectiveness and Durability of Cantilever Racking Solutions

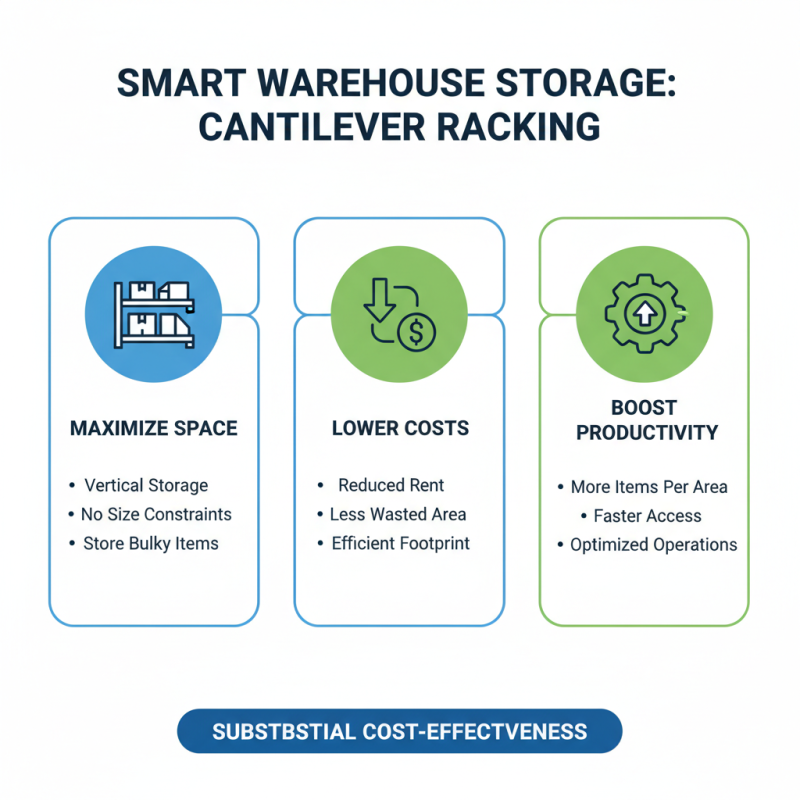

Cantilever racking offers substantial cost-effectiveness for warehouse storage. Its design allows for efficient use of vertical space. Warehouses can store bulky items without worrying about size constraints. This means more items can fit into a smaller area. Reducing wasted space translates to lower rental costs and higher productivity.

Durability is another key benefit of cantilever racking. Made from robust materials, these racks withstand heavy loads and frequent usage. Their long lifespan means less frequent replacements, saving money over time. However, regular maintenance is crucial. Neglecting this can lead to structural issues, which may compromise safety.

Despite its advantages, cantilever racking requires thoughtful planning. Understanding the specific needs of your stored items is essential. Choosing the right height and depth impacts overall efficiency. A miscalculation might result in wasted space or risk of damage. Ongoing assessment will help adapt the racking to changing inventory needs.

Related Posts

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

Why You Should Choose Dexion Pallet Racking for Efficient Warehouse Storage

-

Top 10 Racking and Shelving Systems for Efficient Storage Solutions?

-

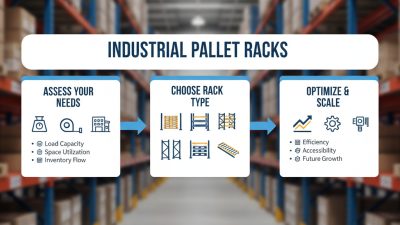

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

10 Best Warehouse Shelving Solutions for Optimal Space Utilization?

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More