WSS Blog

Follow our latest updates and thoughts on our industryTop 2025 Pallet Racking Solutions in Melbourne for Your Warehouse Needs

In today's competitive landscape, efficient warehouse management is essential. Pallet racking Melbourne systems play a crucial role in optimizing space and improving accessibility. These solutions offer flexibility and scalability. They adapt to various storage needs, which is vital for any business.

However, choosing the right pallet racking requires careful consideration. Different types serve unique purposes. Not every system fits every warehouse. Understand the layout and load capacities before deciding. Some may overlook the importance of proper installation. This can lead to inefficiencies and safety hazards.

Despite the availability of many options, not all racking systems are effective. Businesses sometimes settle for less. Assessing long-term needs is essential for making informed choices. The right pallet racking can significantly impact productivity and safety in your warehouse.

Top Factors to Consider When Choosing Pallet Racking Solutions

Choosing the right pallet racking solutions for your warehouse requires careful thought. The first factor to consider is space efficiency. Analyze your warehouse layout. Understand the dimensions and flow of goods. You might underestimate how much space certain racks occupy. Proper planning can eliminate wasted areas.

Weight capacity also plays a crucial role. Each racking system has a limit. Overloading can lead to hazards and costly accidents. It's essential to match the rack's capacity with your inventory requirements. Sometimes, we ignore the importance of regular inspections. Equipment wears over time, affecting strength and safety.

Accessibility is another key aspect. Ensure the racks allow easy access to products. Think about how often items are retrieved. Hard-to-reach areas can increase retrieval times. Observe your team during operations. Are they struggling with heavy lifts or cramped spaces? These insights can guide your decision-making. Your choices can streamline processes and improve safety significantly.

Top 2025 Pallet Racking Solutions in Melbourne

Types of Pallet Racking Systems Available in Melbourne

In Melbourne, various pallet racking systems cater to different warehouse needs. One common type is selective racking, popular for its ease of use. It offers direct access to each pallet, maximizing space efficiency. Reports indicate that selective racking can improve warehouse productivity by 30%. This system is ideal for businesses with diverse inventory.

Another notable option is double-deep racking. This system allows for higher storage density, making it efficient for larger warehouses. However, it can limit access to certain pallets, which may not suit all operations. Studies show that double-deep racking can increase storage capacity by 40%, but also presents challenges in inventory management.

Push-back racking is yet another solution, allowing pallets to be stored on inclined rails. This method enhances space utilization further but requires careful consideration of operational flow. Many warehouses report a 20% increase in storage efficiency with this system. It’s essential to assess unique warehouse dynamics. Not every option works for every operation. Evaluating the pros and cons of each system is crucial for making informed decisions.

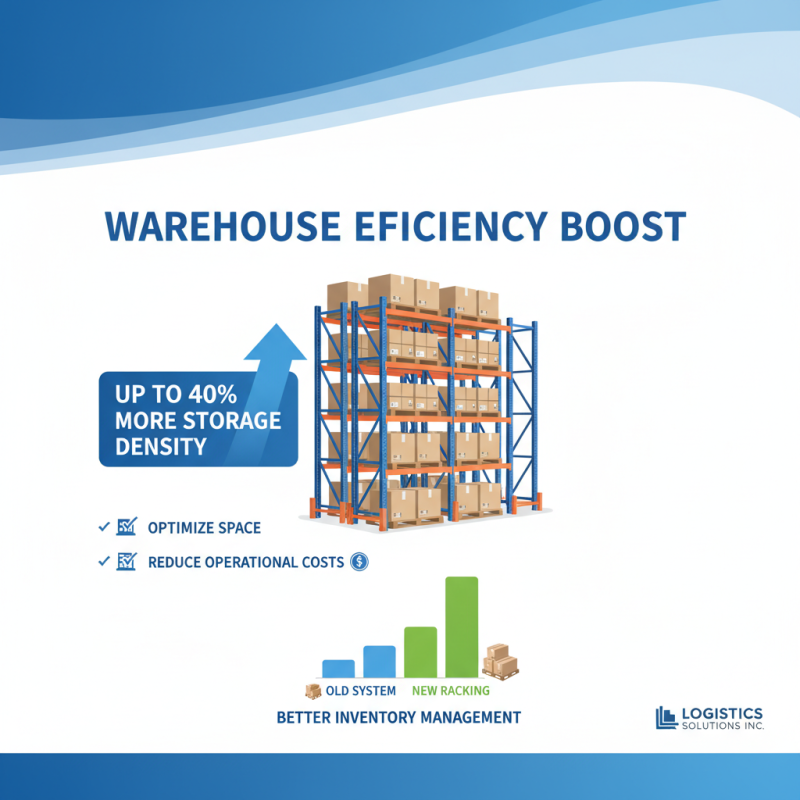

Benefits of Pallet Racking for Warehouse Efficiency

Pallet racking systems significantly enhance warehouse efficiency. According to a recent industry report, effective racking can improve storage density by up to 40%. This increase allows businesses to optimize space and reduce operational costs. More products fit in the same area, leading to better inventory management.

Furthermore, pallet racking facilitates easy access to items. Employees can locate and retrieve products quickly, minimizing downtime. Studies indicate that efficient racking can decrease picking time by approximately 25%. This reduction leads to increased productivity. However, improper implementation can limit these benefits.

In addition, selecting the right racking type is essential. Different types cater to varied warehouse layouts and needs. A recent analysis showed that up to 30% of racking systems fail to maximize space effectively. Mistakes in layout design can hinder warehouse operations. Regular assessments are needed to adapt and improve these systems. Keeping racking solutions updated with industry standards can make a significant difference.

Installation and Maintenance of Pallet Racking Systems

When considering pallet racking systems for your warehouse in Melbourne, installation and maintenance are crucial. A well-installed racking system maximizes space and improves efficiency. According to industry reports, up to 30% of warehouse space can be wasted with improper installations. Ensuring that each rack is installed level and anchored properly is essential to safety and productivity. Regular checks can prevent costly accidents.

Tips: Always consult with professional installers. They know the nuances of racking systems that DIY methods might miss.

Maintenance of pallet racks is just as important. Regular inspections can identify wear and tear before it becomes a serious issue. Experts recommend a thorough inspection every six months. Data shows that facilities that neglect maintenance can increase their risk of structural failure by 40%. Keeping racks clean and ensuring no heavy or fragile items are stored incorrectly helps maintain the integrity of the system.

Tips: Set a monthly maintenance calendar. This small step can save you time and costs in the long run.

Compliance and Safety Standards for Pallet Racking in Warehousing

When selecting pallet racking solutions for warehouses in Melbourne, understanding compliance and safety standards is vital. These standards ensure that your racking systems are both efficient and safe. For example, ensuring that your racking meets Australian safety regulations can save you from potential fines. Regular audits and inspections will help maintain compliance.

Safety is more than a checklist. It involves daily practices. Staff training on proper load limits and racking use can prevent accidents. For instance, workers should be familiar with load heights and weight distribution. Ignoring these can lead to catastrophic failures.

A practical approach to safety includes developing a racking maintenance schedule. This might sound straightforward, yet it often gets overlooked. Regular maintenance checks can reveal issues before they escalate. Also, employees should be empowered to report problems without fear. This creates a proactive culture around safety, essential for any warehouse environment.

Top 2025 Pallet Racking Solutions in Melbourne for Your Warehouse Needs

| Solution Type | Load Capacity (kg) | Height (mm) | Safety Compliance | Key Features |

|---|---|---|---|---|

| Selective Racking | 1500 | 3000 | AS/NZS 4084:2012 | Easy access, versatile configuration |

| Drive-In Racking | 2000 | 4000 | AS/NZS 4084:2012 | Maximizes storage density |

| Pallet Flow Racking | 1200 | 3500 | AS/NZS 4084:2012 | First-in, first-out system |

| Cantilever Racking | 2500 | 5000 | AS/NZS 4084:2012 | Ideal for long and bulky items |

| Shelving Racking | 1000 | 2500 | AS/NZS 4084:2012 | Perfect for smaller items |

Related Posts

-

How to Choose the Best Pallet Racking System for Your Warehouse Needs

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

Ultimate Guide to Dexion Pallet Racking Solutions for Your Warehouse

-

How to Choose the Right Warehouse Storage Racks for Your Business Needs

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More